- Products

Air fine filter GS-PTFE type

空气精过滤器GS-PTFE型

所属分类:

Air fine filter GS-PTFE type

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Air fine filter GS-PTFE type

- Commodity ID: 994906112480075776

空气精过滤器GS-PTFE型

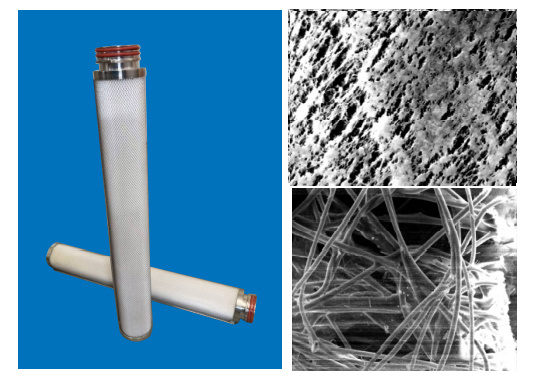

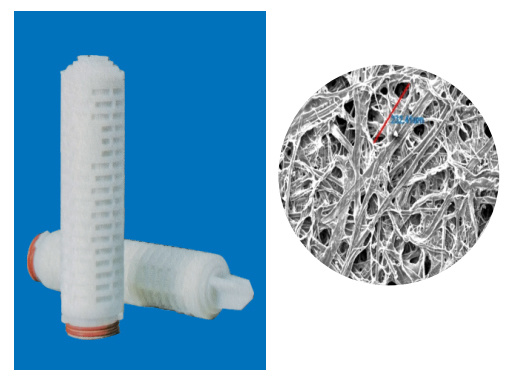

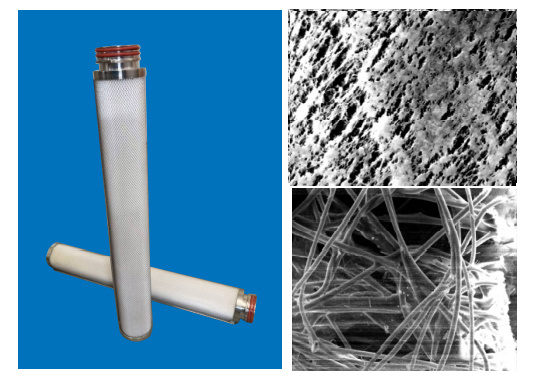

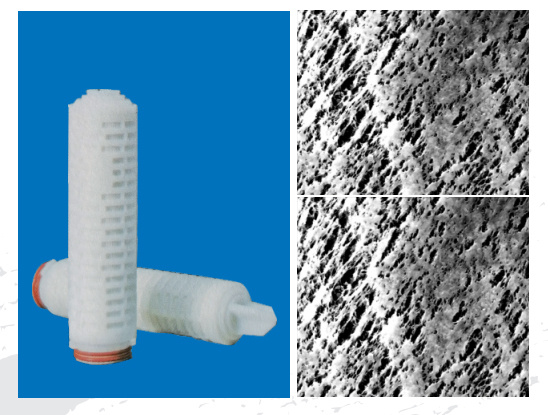

I. Excellent and efficient gas sterilization cartridge GS-PTFE BP seriesGS-PTFE BP series cartridges are made of natural strong hydrophobic PTFE membrane and borosilicate microfiber through a special process , which combines the advantages of two materials and has the dual effect of surface filtration and deep filtration, and is unique in the domestic air filtration industry. It can pass the gas bacterial challenge test with a cartridge challenge level of not less than 107 CFU/㎝2, and Pseudomonas aeruginosa ATCC19146 LRV>7, which is suitable for air terminal sterilization filtration of high oxygen-consuming microorganism fermentation. The 100% integrity test before shipment ensures stable product quality and is widely used for terminal gas decontamination filtration of antibiotics, amino acids, enzymes and polysaccharides.Main FeaturesNatural strong hydrophobic, breathable and waterproof

High flux, low pressure difference, anti-aging, long life

High temperature resistance, can withstand multiple online steam sterilization

100% integrity testing of cartridge before deliveryTypical ApplicationsSterilization and filtration of compressed air for the microbial fermentation industry

Sterilization and filtration of air with high oxygen consumption and low pressure drop

Sterilization and filtration of corrosive gases

Material StructureFilter material: hydrophobic PTFE membrane and borosilicate microfiber

Material StructureFilter material: hydrophobic PTFE membrane and borosilicate microfiber

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: reinforced polypropylene

Center tube: polypropylene or stainless steel

O-ring: see cartridge selection table

Sealing technology: heat fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.01

Filtration efficiency: 99.9999%

Effective filtration area: 0.55㎡/10"

Initial pressure drop(MPa):≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilizable 123±2℃/30min 150 times

Integrity testing

See the accompanying product quality assurance certificateOrdering InformationGS-PTFE BP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable II. Super high temperature resistant gas sterilization cartridge GS-PTFE BP/ss seriesGS-PTFE BP/ss series cartridges are made of natural strong hydrophobic PTFE membrane and borosilicate microfiber through a special process , which combines the advantages of two materials and has the dual effect of surface filtration and deep filtration, and is unique in the domestic air filtration industry. The inner and outer cartridge frames, ports and end caps are all made of stainless steel, which is especially suitable for production where the temperature fluctuation of steam sterilization is high. The cartridge can pass the gas bacterial challenge test with a cartridge challenge level of 107 CFU/㎝2 or less, and Pseudomonas aeruginosa ATCC19146 LRV>7, making it suitable for air terminal decontamination filtration for high oxygen-consuming microbial fermentation. The 100% integrity test before shipment ensures stable product quality and is widely used for terminal gas decontamination filtration of antibiotics, amino acids, enzymes and polysaccharides.

Main FeaturesNatural strong hydrophobic, breathable and waterproof

High flux, low pressure difference, anti-aging

Long life, high temperature resistance, can withstand multiple times

Online steam sterilization, 100% integrity testing of cartridge before deliveryTypical ApplicationsSterilization and filtration of compressed air for the microbial fermentation industry

Sterilization and filtration of air with high oxygen consumption and low pressure drop

Sterilization and filtration of corrosive gasesOperating parametersMaximum working temperature: <80℃

Maximum working pressure difference: forward: 0.4MPa@25℃ 0.2MPa@80℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesMaterial Structure

Filter material: hydrophobic polytetrafluoroethylene membrane and borosilicate microfiber

Support layer/Infusion layer: Polypropylene/Polyester

Housing/end caps: All stainless steel

Center tube: Stainless steel

O-ring: see cartridge selection table

Sealing technology: Heat seal technology Adhesive bondingCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥ 107 CFU/cm2 @ATCC19146

Effective filtration surface area: 0.55㎡/10"

Initial pressure drop (MPa): ≤0.005

Ordering Information

GS-PTFE BP//SS Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 11=226(stainless steel) SP = flat head (stainless steel) S=Silicone rubber

E=Ethylene-Propylene

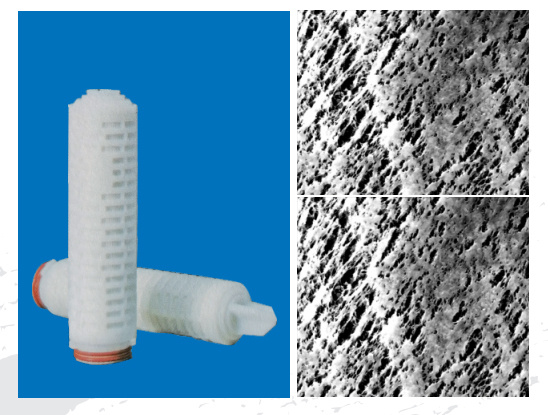

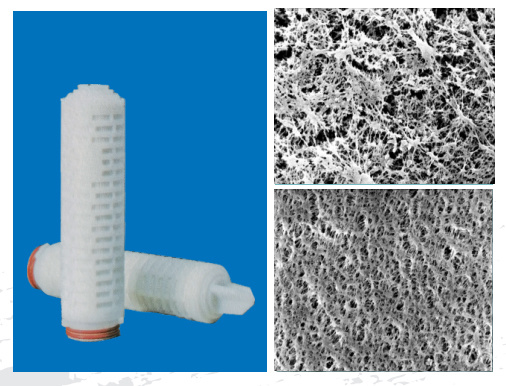

V=FluoroelastomerR = sterilizable Ⅲ、 A new generation of high-precision safeguard gas sterilization cartridge GS-PTFE HP seriesGS-PTFE HP series cartridge is made of natural strong hydrophobic PTFE membrane, designed for microbial oxygen-consuming fermentation sterile gas filtration, which greatly improves the retention capacity of microorganisms. It is especially suitable for high relative humidity of air and sterile preparation air decontamination filtration, and can pass the harsh liquid bacteria challenge test if the cartridge challenge level is not lower than 107CFU/㎝2EFA, which maximally ensures that the user's important products or fermentation broth are not contaminated with defective Pseudomonas ATCC19146 LRV>7. 100% integrity test before leaving the factory and associated with Bacterial challenge test associated with the product to ensure stable quality, widely used in antibiotics, amino acids, enzymes, polysaccharides, beer and other fermentation industries, as well as sterile preparations of terminal gas decontamination filtration.Main features

Natural strong hydrophobic, breathable and waterproof

Long life, high temperature resistance, can withstand multiple in-line steam sterilization

Wide range of chemical compatibility

100% integrity testing of cartridge before deliveryTypical applications

Microbial fermentation air with high relative humidity gas sterilization filtration

Sterile filtration of gases for aseptic packaging

Sterile breather filtration for storage tanks

Sterilization and filtration of corrosive gases, organic solvent filtration

Material structure

Material structure

Filter material: double layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Shell/end caps/fins: reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Effective filtration area: 0.7㎡/10"

Initial pressure drop (MPa): ≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity test value See random product quality assurance certificateOrdering InformationGS-PTFE HP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable Order Information:For special model specifications, please contact the sales department of Shanghai Filter Co. Tel:021-56151124 Fax:021-56807944

Ⅳ、A new generation of super high temperature resistant sterilization gas sterilization cartridge GS-PTFE HP/ss series

GS-PTFE HP/ss series cartridge is made of natural strong hydrophobic PTFE membrane, and the inner and outer cartridge skeleton, interface and end cap are all made of stainless steel, which is especially suitable for production occasions with large temperature fluctuations of steam disinfection. It is specially designed for microbial oxygen-consuming fermentation and sterile gas filtration, which greatly improves the retention capacity of microorganisms. Especially suitable for high relative humidity of air and aseptic preparation air sterilization filtration, in the cartridge challenge level of not less than 107CFU/cm2, can pass the most demanding liquid bacteria challenge test, the maximum degree of assurance that the user's important products or fermentation broth is not contaminated, defective Pseudomonas ATCC19146 LRV>7. 100% integrity test before leaving the factory, and with the bacteria It is widely used in antibiotics, amino acids, enzymes, polysaccharides, beer and other fermentation industries as well as sterile preparations for terminal gas filtration.Main features

Natural strong hydrophobic, breathable and waterproof

Long life, high temperature resistance, can withstand multiple in-line steam sterilization

Wide range of chemical compatibility

100% integrity testing of cartridge before deliveryTypical applications

Microbial fermentation air with high relative humidity gas sterilization filtration

Sterile filtration of gases for aseptic packaging, sterile breather filtration for storage tanks

Sterilization and filtration of corrosive gases, filtration of organic solventsOperating parameters

Maximum working temperature: <80℃

Max. working pressure difference: forward: 0.4MPa@25℃ 0.2MPa@80℃

Sterilization method: online steam sterilization 123±2℃/30min 150 timesMaterial structure

Filter material: double layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Housing/end cap/fin: Stainless steel

Center tube: stainless steel

O-ring: see cartridge selection table

Sealing technology: hot melt/adhesive bondingCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (um): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Effective filtration area: 0.7m2/10"

Initial pressure drop (MPa): ≤0.005

Integrity testing See accompanying product quality guarantee

Ordering Information

GS-PTFE BP//SS Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 11=226(stainless steel) SP = flat head (stainless steel) S=Silicone rubber

E=Ethylene-Propylene

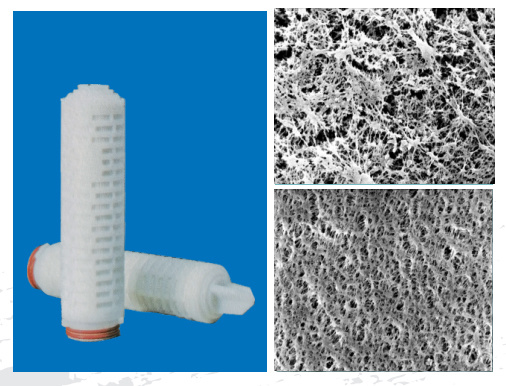

V=FluoroelastomerR = sterilizable V. High-precision and high-assurance gas sterilization cartridge GS-PTFE WP seriesGS-PTFE WP series cartridge adopts imported high-precision PTFE biaxially oriented membrane, which has the advantages of uniform pore size, thinness and thickness as well as high void rate, especially suitable for air sterilization filtration of fermentation products with high relative humidity of air and sensitive to contaminated bacterium. In the case of cartridge challenge level not less than 107CFU/cm2, it can pass the most demanding liquid bacterial challenge test to ensure the user's important products or fermentation broth is not contaminated to the maximum extent, defective Pseudomonas ATCC19146LRV>7. 100% integrity test before leaving the factory, and associated with the bacterial challenge test to ensure stable product quality, widely used in It is widely used in antibiotics, amino acids, enzymes, polysaccharides and beer fermentation industries as well as in end gas filtration of sterile preparations.Main features

Natural strong hydrophobic, breathable and waterproof

Large flux, low pressure difference, anti-aging

High filtration precision, high anti-bacteria safety performance

Wide range of chemical compatibility, 100% integrity testing of cartridge before deliveryTypical applications

Sterilization and filtration of high humidity air in microbial fermentation industry

Air filtration for phage-sensitive fermentation products

Sterile breather filtration for storage tanks

Sterile preparation protective gas filtration, organic solvent filtration

Material structure

Material structure

Filter material: high strength hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Shell/end caps/fins: reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.003

Bacteria retention: ≥107 CFU/cm2@ATCC19146

Effective filtration area: 0.7㎡/10"

Initial pressure drop (MPa):≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity testing See the accompanying product quality assurance sheetGS-PTFE WP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0003=0.003µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

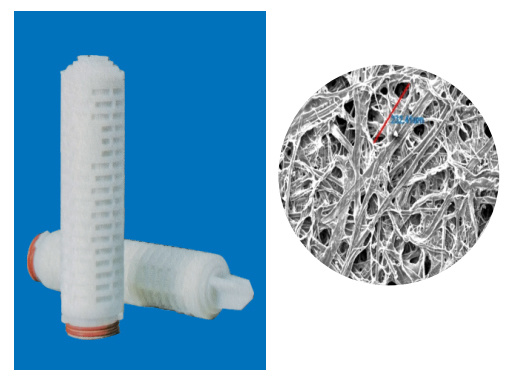

V=FluoroelastomerR = sterilizable Ⅵ、Super high flow gas sterilization cartridge GS-PTFE NB seriesGS-PTFE NB series cartridges are made of borosilicate fiber coated with PTFE, which has 95% dust holding space of super fine borosilicate fiber and strong hydrophobicity and toughness of PTFE, so it has the advantages of super high air flow, low pressure drop and large dirt holding capacity. The product has been on the market for more than 20 years since 1995, and to this day, some of the leading antibiotic companies still insist on using NB cartridges with 95% dust holding space. The cartridge has passed the aerosol (PAO) challenge test and the gaseous bacteria challenge test, and is suitable for microbial fermentation air filtration with high oxygen consumption and dry air. 100% integrity testing prior to shipment and correlation with PAO challenge testing ensures consistent quality for end-use gas filtration of antibiotics, amino acids, enzymes and polysaccharides.Main features

High flux, low pressure difference, anti-aging

Good hydrophobicity, large dust capacity

Long life, high temperature resistance, and multiple online steam sterilization resistance

100% integrity testing of cartridge before deliveryTypical applications

De-bacterization and filtration of dry compressed air in fermentation industry

High oxygen consumption and low pressure drop air decontamination filtration

Ultra-pure gas filtration

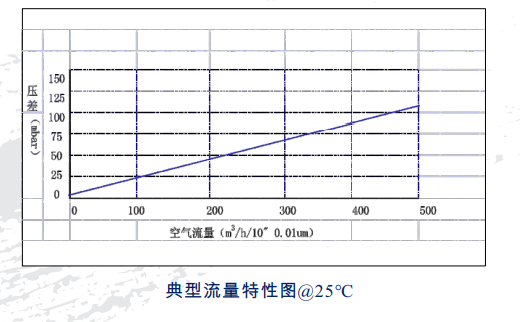

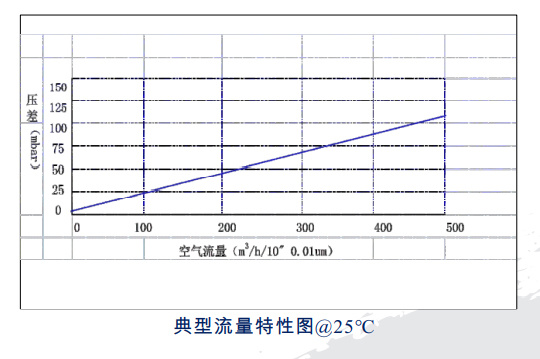

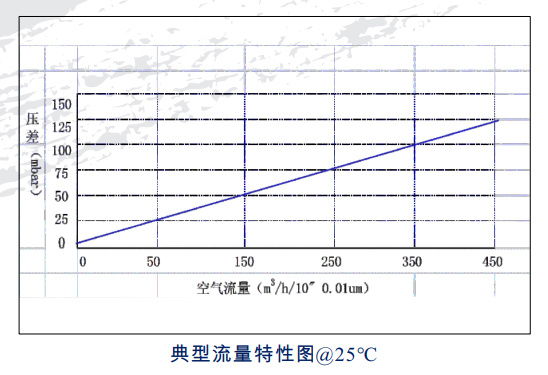

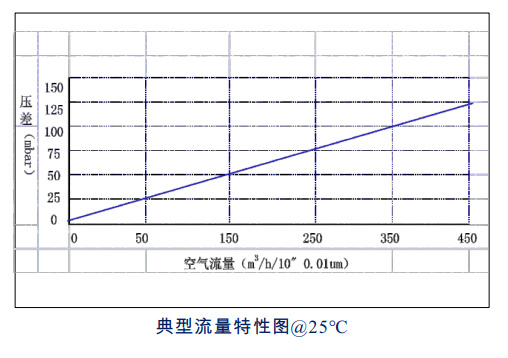

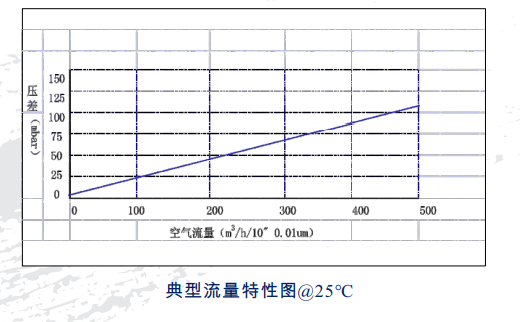

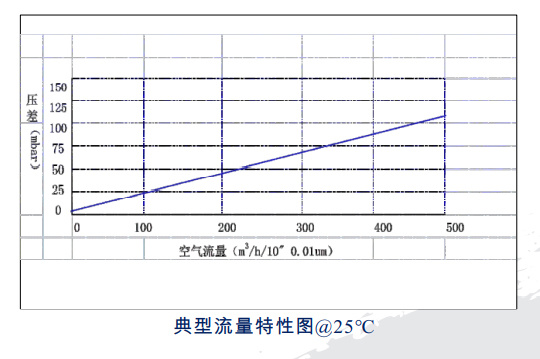

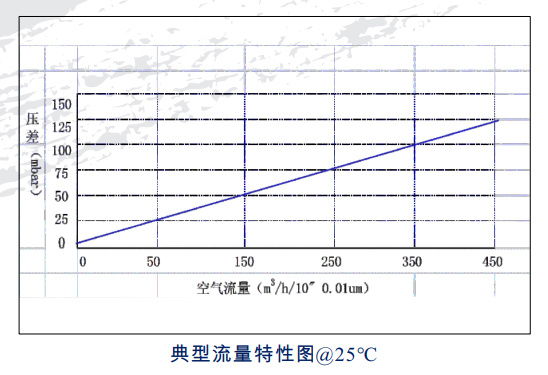

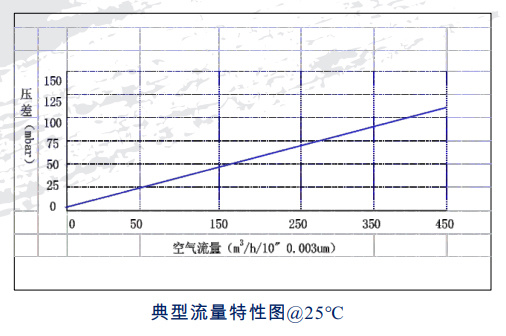

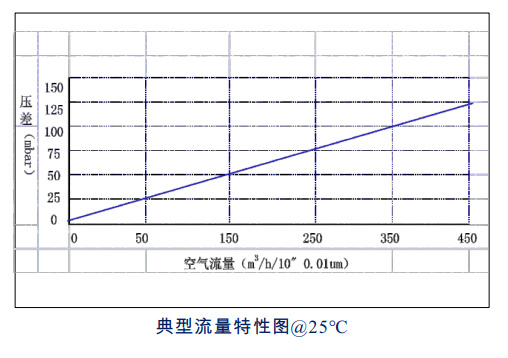

10"折叠滤芯流量特性@25℃

Material structure

Material structure

Filter material: borosilicate microfiber cloaked with PTFE

Support layer/flow guide layer: polypropylene/polypropylene

Shell/end caps/fins: reinforced polypropylene or stainless steel

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: report cartridge selection table

Sealing technology: heat fusion sealing technology (plastic skeleton)

Adhesive bonding (all stainless steel skeleton)Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity testing: see the accompanying product quality assurance sheet

Cartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.01

Filtration efficiency: 99.9999%

Effective filtration area: 0.4㎡/10"

Initial pressure drop(MPa):≤0.005Ordering Information

GS-PTFE NB Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

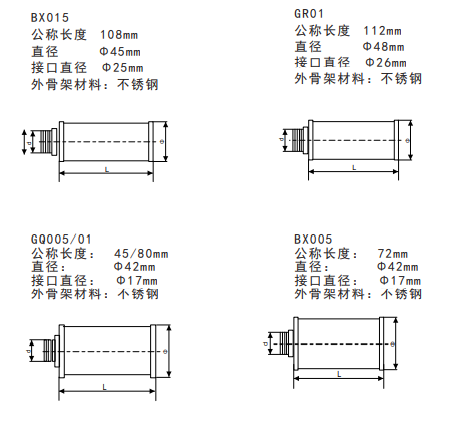

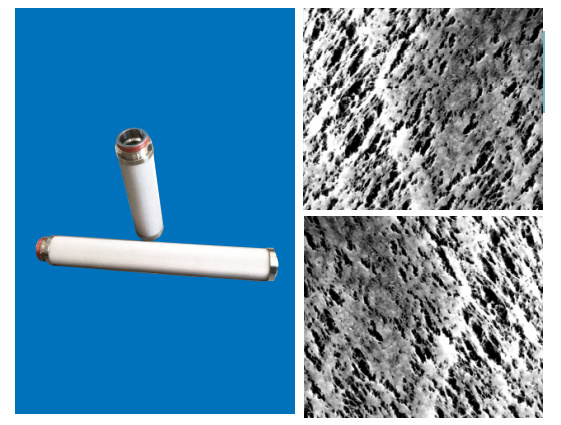

V=FluoroelastomerR = sterilizable Ⅶ、Small-scale air filter cartridge for test tube irrigation GS-PTFE series

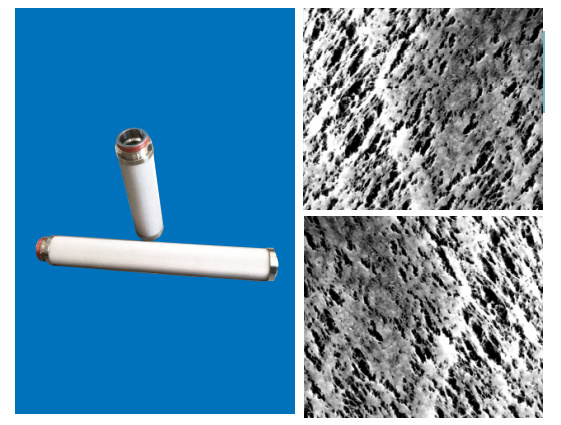

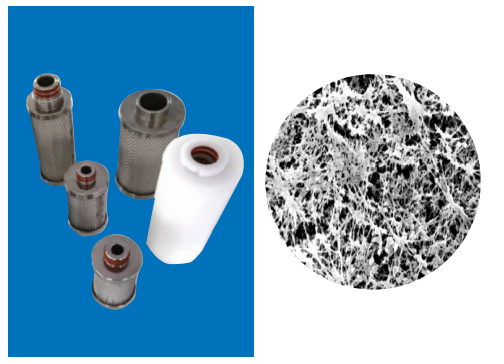

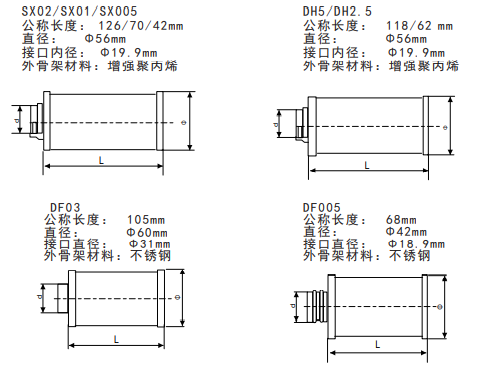

Small size air sterilization filter is generally used for 10L-300L fermentation test tank, its sterility requirements are high, must be specially designed. Ltd. was the first to cooperate with the National Biochemical Engineering and Technology Research Center (Shanghai) for the test tank air sterilization filter, and the users are all over the country's universities and colleges, scientific research institutes and enterprise technology centers, so we have accumulated rich application experience in this field. The new generation of small-size cartridge adopts high-accuracy and high-strength PTFE membrane, which has more excellent filtration performance and reliable sterilization filtration performance in dry or humid conditions.

Material structure.

Filter material: high-precision hydrophobic PTFE membrane

Support layer/infusion layer: polypropylene

Housing/end cap: stainless steel or reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: silicone rubber / EPDM / fluorine rubber

Sealing technology: adhesive bonding (stainless steel skeleton) and heat fusion sealing technology (plastic skeleton)Filter element parameters

Filtration precision (um): 0.01, 0.003

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Initial pressure drop (MPa): ≤0.005Operating parameters

Maximum working temperature: <80℃

Maximum working pressure difference: forward:0.4MPa@25°C 0.2MPa@80°C

Reverse:0.2MPa@25°C

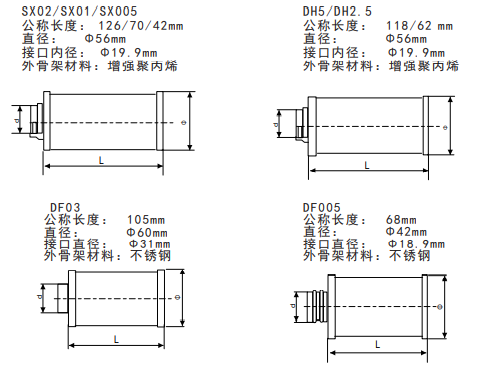

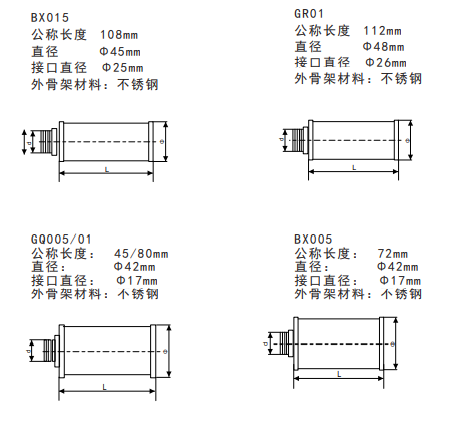

Sterilization mode: online steam sterilization 123±2°C/30min 150 timesFilter form factor and selection table Specification Model Cartridge configuration Filtration flux

(L/min)Cylinder diameter

(mm)Total height(mm) GS-PTFE-005 Φ56×42 50~80 76 175 GS-PTFE-01 Φ56×70 100~150 76 201 GS-PTFE-02 Φ56×126 200~300 76 240

-

GS-PTFE type folded cartridge type air fine filter

The GS-PTFE air filter housing is designed, manufactured, inspected and accepted in accordance with GB 150-2011 "Pressure Vessel", and the equipment is processed in accordance with JB/T 4709-2007 "Welding Procedure for Steel Pressure Vessels" and JB/T 4730-2016 "Pressure-bearing Equipment Nondestructive Testing", and the flange standard is adopted from HG/T 20592-2009 PN series. The air filter housing is designed with the best air flow and the suspended cartridge insert, which has the advantages of low pressure drop and no condensate accumulation. The filter cartridge socket uses a double seal 226 snap-in type to ensure reliable sealing and filtration effect. The top and bottom of the cartridge are flanged, and the housing is made of 304 stainless steel. The air inlet pipe is reserved for steam disinfection flange, which not only saves cost but also facilitates installation. The inner surface of the housing is mechanically polished, and the conventional working pressure is 0.4MPa, other working pressure housing is also available.

♦ GS-PTFE air fine filter outline size and selection table

Product Model Cartridge configuration Filtration flux

Nm3/minExternal dimensions (mm) D

L

H

h

d (import/export) GS-PTFE-05

1×5ˮ

0.5

91.5

260

380

No legs DN20 PN16

GS-PTFE-1

1

GS-PTFE-2

1×10ˮ

2

505

DN25 PN16

GS-PTFE-3

3

515

DN40 PN16

GS-PTFE-4

1×20ˮ

4

765

DN40 PN16

GS-PTFE-5

3×10ˮ

5

186

350

750

300

DN50 PN16

GS-PTFE-10

3×20ˮ

10

1030

DN65 PN16

GS-PTFE-15

4×20ˮ

15

256

440

1115

320

DN80 PN16

GS-PTFE-20

5×20ˮ

20

1130

DN100 PN16

GS-PTFE-30

7×20ˮ

30

GS-PTFE-40

9×20ˮ

40

306

503

1205

350

DN125 PN16

GS-PTFE-50

11×20ˮ

50

356

585

1335

440

GS-PTFE-60

12×20ˮ

60

GS-PTFE-80

15×20ˮ

80

406

630

1380

DN150 PN16

GS-PTFE-100

18×20ˮ

100

GS-PTFE-120

21×20ˮ

120

456

670

1465

DN200 PN16

GS-PTFE-150

24×20ˮ

150

506

730

1550

500

GS-PTFE-180

27×20ˮ

180

1585

DN250 PN16

GS-PTFE-200

30×20ˮ

200

558

790

1640

GS-PTFE-250

36×20ˮ

240

608

910

1780

600

DN300 PN16

GS-PTFE-300

45×20ˮ

300

658

965

1865

650

GS-PTFE-360

60×20ˮ

360

858

1210

2215

820

DN350 PN16

GS-PTFE-400

65×20"

400

2215

DN350 PN16

Note: 1. can be specially designed and processed according to user requirements.

2. . The filtration flux is calculated according to the inlet pressure of 0.2MPa (gauge pressure) and the differential pressure of 0.01MPa. -

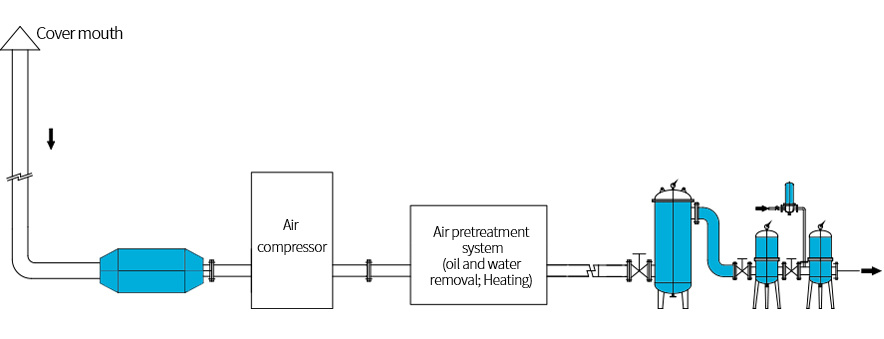

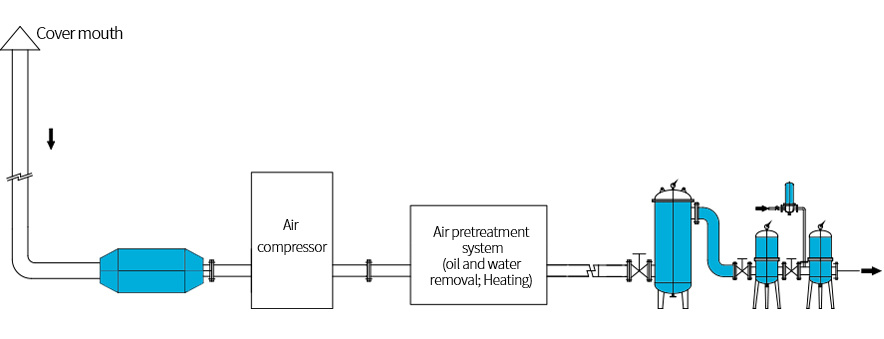

Fermentation compressed air filtration system (I)

Air compressor picking filter GS-A type

This series is used for air compressor inlet filtration

Air Master Filter GS-B1

The cartridge is made of folded fiber filter paper or reinforced glass fiber, which has the advantages of large filtration area, small differential pressure, large flow rate and long life.

Air pre-filter GS-B2

Made of ultra-fine glass fiber material with 0.3µm filtration accuracy and up to 95% dust holding space.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Air Fine Filter GS-PTFE

Made of natural strong hydrophobic PTFE membrane and borosilicate microfiber compounded by a special process (Invention Patent No. 03129430.8, 200510024216.2)

Air fine filter GS-PTFE type

空气精过滤器GS-PTFE型

Category:

Air fine filter GS-PTFE type

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Air fine filter GS-PTFE type

- Commodity ID: 994906112480075776

空气精过滤器GS-PTFE型

I. Excellent and efficient gas sterilization cartridge GS-PTFE BP seriesGS-PTFE BP series cartridges are made of natural strong hydrophobic PTFE membrane and borosilicate microfiber through a special process , which combines the advantages of two materials and has the dual effect of surface filtration and deep filtration, and is unique in the domestic air filtration industry. It can pass the gas bacterial challenge test with a cartridge challenge level of not less than 107 CFU/㎝2, and Pseudomonas aeruginosa ATCC19146 LRV>7, which is suitable for air terminal sterilization filtration of high oxygen-consuming microorganism fermentation. The 100% integrity test before shipment ensures stable product quality and is widely used for terminal gas decontamination filtration of antibiotics, amino acids, enzymes and polysaccharides.Main FeaturesNatural strong hydrophobic, breathable and waterproof

High flux, low pressure difference, anti-aging, long life

High temperature resistance, can withstand multiple online steam sterilization

100% integrity testing of cartridge before deliveryTypical ApplicationsSterilization and filtration of compressed air for the microbial fermentation industry

Sterilization and filtration of air with high oxygen consumption and low pressure drop

Sterilization and filtration of corrosive gases

Material StructureFilter material: hydrophobic PTFE membrane and borosilicate microfiber

Material StructureFilter material: hydrophobic PTFE membrane and borosilicate microfiber

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: reinforced polypropylene

Center tube: polypropylene or stainless steel

O-ring: see cartridge selection table

Sealing technology: heat fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.01

Filtration efficiency: 99.9999%

Effective filtration area: 0.55㎡/10"

Initial pressure drop(MPa):≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilizable 123±2℃/30min 150 times

Integrity testing

See the accompanying product quality assurance certificateOrdering InformationGS-PTFE BP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable II. Super high temperature resistant gas sterilization cartridge GS-PTFE BP/ss seriesGS-PTFE BP/ss series cartridges are made of natural strong hydrophobic PTFE membrane and borosilicate microfiber through a special process , which combines the advantages of two materials and has the dual effect of surface filtration and deep filtration, and is unique in the domestic air filtration industry. The inner and outer cartridge frames, ports and end caps are all made of stainless steel, which is especially suitable for production where the temperature fluctuation of steam sterilization is high. The cartridge can pass the gas bacterial challenge test with a cartridge challenge level of 107 CFU/㎝2 or less, and Pseudomonas aeruginosa ATCC19146 LRV>7, making it suitable for air terminal decontamination filtration for high oxygen-consuming microbial fermentation. The 100% integrity test before shipment ensures stable product quality and is widely used for terminal gas decontamination filtration of antibiotics, amino acids, enzymes and polysaccharides.

Main FeaturesNatural strong hydrophobic, breathable and waterproof

High flux, low pressure difference, anti-aging

Long life, high temperature resistance, can withstand multiple times

Online steam sterilization, 100% integrity testing of cartridge before deliveryTypical ApplicationsSterilization and filtration of compressed air for the microbial fermentation industry

Sterilization and filtration of air with high oxygen consumption and low pressure drop

Sterilization and filtration of corrosive gasesOperating parametersMaximum working temperature: <80℃

Maximum working pressure difference: forward: 0.4MPa@25℃ 0.2MPa@80℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesMaterial Structure

Filter material: hydrophobic polytetrafluoroethylene membrane and borosilicate microfiber

Support layer/Infusion layer: Polypropylene/Polyester

Housing/end caps: All stainless steel

Center tube: Stainless steel

O-ring: see cartridge selection table

Sealing technology: Heat seal technology Adhesive bondingCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥ 107 CFU/cm2 @ATCC19146

Effective filtration surface area: 0.55㎡/10"

Initial pressure drop (MPa): ≤0.005

Ordering Information

GS-PTFE BP//SS Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 11=226(stainless steel) SP = flat head (stainless steel) S=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable Ⅲ、 A new generation of high-precision safeguard gas sterilization cartridge GS-PTFE HP seriesGS-PTFE HP series cartridge is made of natural strong hydrophobic PTFE membrane, designed for microbial oxygen-consuming fermentation sterile gas filtration, which greatly improves the retention capacity of microorganisms. It is especially suitable for high relative humidity of air and sterile preparation air decontamination filtration, and can pass the harsh liquid bacteria challenge test if the cartridge challenge level is not lower than 107CFU/㎝2EFA, which maximally ensures that the user's important products or fermentation broth are not contaminated with defective Pseudomonas ATCC19146 LRV>7. 100% integrity test before leaving the factory and associated with Bacterial challenge test associated with the product to ensure stable quality, widely used in antibiotics, amino acids, enzymes, polysaccharides, beer and other fermentation industries, as well as sterile preparations of terminal gas decontamination filtration.Main features

Natural strong hydrophobic, breathable and waterproof

Long life, high temperature resistance, can withstand multiple in-line steam sterilization

Wide range of chemical compatibility

100% integrity testing of cartridge before deliveryTypical applications

Microbial fermentation air with high relative humidity gas sterilization filtration

Sterile filtration of gases for aseptic packaging

Sterile breather filtration for storage tanks

Sterilization and filtration of corrosive gases, organic solvent filtration

Material structure

Material structure

Filter material: double layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Shell/end caps/fins: reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Effective filtration area: 0.7㎡/10"

Initial pressure drop (MPa): ≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity test value See random product quality assurance certificateOrdering InformationGS-PTFE HP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable Order Information:For special model specifications, please contact the sales department of Shanghai Filter Co. Tel:021-56151124 Fax:021-56807944

Ⅳ、A new generation of super high temperature resistant sterilization gas sterilization cartridge GS-PTFE HP/ss series

GS-PTFE HP/ss series cartridge is made of natural strong hydrophobic PTFE membrane, and the inner and outer cartridge skeleton, interface and end cap are all made of stainless steel, which is especially suitable for production occasions with large temperature fluctuations of steam disinfection. It is specially designed for microbial oxygen-consuming fermentation and sterile gas filtration, which greatly improves the retention capacity of microorganisms. Especially suitable for high relative humidity of air and aseptic preparation air sterilization filtration, in the cartridge challenge level of not less than 107CFU/cm2, can pass the most demanding liquid bacteria challenge test, the maximum degree of assurance that the user's important products or fermentation broth is not contaminated, defective Pseudomonas ATCC19146 LRV>7. 100% integrity test before leaving the factory, and with the bacteria It is widely used in antibiotics, amino acids, enzymes, polysaccharides, beer and other fermentation industries as well as sterile preparations for terminal gas filtration.Main features

Natural strong hydrophobic, breathable and waterproof

Long life, high temperature resistance, can withstand multiple in-line steam sterilization

Wide range of chemical compatibility

100% integrity testing of cartridge before deliveryTypical applications

Microbial fermentation air with high relative humidity gas sterilization filtration

Sterile filtration of gases for aseptic packaging, sterile breather filtration for storage tanks

Sterilization and filtration of corrosive gases, filtration of organic solventsOperating parameters

Maximum working temperature: <80℃

Max. working pressure difference: forward: 0.4MPa@25℃ 0.2MPa@80℃

Sterilization method: online steam sterilization 123±2℃/30min 150 timesMaterial structure

Filter material: double layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Housing/end cap/fin: Stainless steel

Center tube: stainless steel

O-ring: see cartridge selection table

Sealing technology: hot melt/adhesive bondingCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (um): 0.01

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Effective filtration area: 0.7m2/10"

Initial pressure drop (MPa): ≤0.005

Integrity testing See accompanying product quality guarantee

Ordering Information

GS-PTFE BP//SS Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 11=226(stainless steel) SP = flat head (stainless steel) S=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable V. High-precision and high-assurance gas sterilization cartridge GS-PTFE WP seriesGS-PTFE WP series cartridge adopts imported high-precision PTFE biaxially oriented membrane, which has the advantages of uniform pore size, thinness and thickness as well as high void rate, especially suitable for air sterilization filtration of fermentation products with high relative humidity of air and sensitive to contaminated bacterium. In the case of cartridge challenge level not less than 107CFU/cm2, it can pass the most demanding liquid bacterial challenge test to ensure the user's important products or fermentation broth is not contaminated to the maximum extent, defective Pseudomonas ATCC19146LRV>7. 100% integrity test before leaving the factory, and associated with the bacterial challenge test to ensure stable product quality, widely used in It is widely used in antibiotics, amino acids, enzymes, polysaccharides and beer fermentation industries as well as in end gas filtration of sterile preparations.Main features

Natural strong hydrophobic, breathable and waterproof

Large flux, low pressure difference, anti-aging

High filtration precision, high anti-bacteria safety performance

Wide range of chemical compatibility, 100% integrity testing of cartridge before deliveryTypical applications

Sterilization and filtration of high humidity air in microbial fermentation industry

Air filtration for phage-sensitive fermentation products

Sterile breather filtration for storage tanks

Sterile preparation protective gas filtration, organic solvent filtration

Material structure

Material structure

Filter material: high strength hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene / polyester

Shell/end caps/fins: reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.003

Bacteria retention: ≥107 CFU/cm2@ATCC19146

Effective filtration area: 0.7㎡/10"

Initial pressure drop (MPa):≤0.005Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity testing See the accompanying product quality assurance sheetGS-PTFE WP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0003=0.003µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable Ⅵ、Super high flow gas sterilization cartridge GS-PTFE NB seriesGS-PTFE NB series cartridges are made of borosilicate fiber coated with PTFE, which has 95% dust holding space of super fine borosilicate fiber and strong hydrophobicity and toughness of PTFE, so it has the advantages of super high air flow, low pressure drop and large dirt holding capacity. The product has been on the market for more than 20 years since 1995, and to this day, some of the leading antibiotic companies still insist on using NB cartridges with 95% dust holding space. The cartridge has passed the aerosol (PAO) challenge test and the gaseous bacteria challenge test, and is suitable for microbial fermentation air filtration with high oxygen consumption and dry air. 100% integrity testing prior to shipment and correlation with PAO challenge testing ensures consistent quality for end-use gas filtration of antibiotics, amino acids, enzymes and polysaccharides.Main features

High flux, low pressure difference, anti-aging

Good hydrophobicity, large dust capacity

Long life, high temperature resistance, and multiple online steam sterilization resistance

100% integrity testing of cartridge before deliveryTypical applications

De-bacterization and filtration of dry compressed air in fermentation industry

High oxygen consumption and low pressure drop air decontamination filtration

Ultra-pure gas filtration

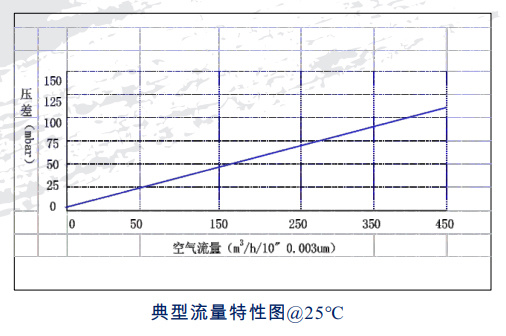

10"折叠滤芯流量特性@25℃

Material structure

Material structure

Filter material: borosilicate microfiber cloaked with PTFE

Support layer/flow guide layer: polypropylene/polypropylene

Shell/end caps/fins: reinforced polypropylene or stainless steel

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: report cartridge selection table

Sealing technology: heat fusion sealing technology (plastic skeleton)

Adhesive bonding (all stainless steel skeleton)Operating parameters

Maximum working temperature: <80℃

Max. working pressure difference:Forward:0.4MPa@25℃ 0.2MPa@80℃

Reverse: 0.2MPa@25℃

Sterilization mode: online steam sterilization 123±2℃/30min 150 timesIntegrity testing: see the accompanying product quality assurance sheet

Cartridge parameters

Outer diameter: Φ70

Length: 5", 10", 20", 30"

Filtration precision (µm):0.01

Filtration efficiency: 99.9999%

Effective filtration area: 0.4㎡/10"

Initial pressure drop(MPa):≤0.005Ordering Information

GS-PTFE NB Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"0001=0.01µm 5=226(Outer steel ring lining)

2=226(Regular)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable Ⅶ、Small-scale air filter cartridge for test tube irrigation GS-PTFE series

Small size air sterilization filter is generally used for 10L-300L fermentation test tank, its sterility requirements are high, must be specially designed. Ltd. was the first to cooperate with the National Biochemical Engineering and Technology Research Center (Shanghai) for the test tank air sterilization filter, and the users are all over the country's universities and colleges, scientific research institutes and enterprise technology centers, so we have accumulated rich application experience in this field. The new generation of small-size cartridge adopts high-accuracy and high-strength PTFE membrane, which has more excellent filtration performance and reliable sterilization filtration performance in dry or humid conditions.

Material structure.

Filter material: high-precision hydrophobic PTFE membrane

Support layer/infusion layer: polypropylene

Housing/end cap: stainless steel or reinforced polypropylene

Center tube: stainless steel or temperature and pressure resistant polypropylene

O-ring: silicone rubber / EPDM / fluorine rubber

Sealing technology: adhesive bonding (stainless steel skeleton) and heat fusion sealing technology (plastic skeleton)Filter element parameters

Filtration precision (um): 0.01, 0.003

Filtration efficiency: 99.9999%

Bacteria retention: ≥107CFU/cm2@ATCC19146

Initial pressure drop (MPa): ≤0.005Operating parameters

Maximum working temperature: <80℃

Maximum working pressure difference: forward:0.4MPa@25°C 0.2MPa@80°C

Reverse:0.2MPa@25°C

Sterilization mode: online steam sterilization 123±2°C/30min 150 timesFilter form factor and selection table Specification Model Cartridge configuration Filtration flux

(L/min)Cylinder diameter

(mm)Total height(mm) GS-PTFE-005 Φ56×42 50~80 76 175 GS-PTFE-01 Φ56×70 100~150 76 201 GS-PTFE-02 Φ56×126 200~300 76 240

-

GS-PTFE type folded cartridge type air fine filter

The GS-PTFE air filter housing is designed, manufactured, inspected and accepted in accordance with GB 150-2011 "Pressure Vessel", and the equipment is processed in accordance with JB/T 4709-2007 "Welding Procedure for Steel Pressure Vessels" and JB/T 4730-2016 "Pressure-bearing Equipment Nondestructive Testing", and the flange standard is adopted from HG/T 20592-2009 PN series. The air filter housing is designed with the best air flow and the suspended cartridge insert, which has the advantages of low pressure drop and no condensate accumulation. The filter cartridge socket uses a double seal 226 snap-in type to ensure reliable sealing and filtration effect. The top and bottom of the cartridge are flanged, and the housing is made of 304 stainless steel. The air inlet pipe is reserved for steam disinfection flange, which not only saves cost but also facilitates installation. The inner surface of the housing is mechanically polished, and the conventional working pressure is 0.4MPa, other working pressure housing is also available.

♦ GS-PTFE air fine filter outline size and selection table

Product Model Cartridge configuration Filtration flux

Nm3/minExternal dimensions (mm) D

L

H

h

d (import/export) GS-PTFE-05

1×5ˮ

0.5

91.5

260

380

No legs DN20 PN16

GS-PTFE-1

1

GS-PTFE-2

1×10ˮ

2

505

DN25 PN16

GS-PTFE-3

3

515

DN40 PN16

GS-PTFE-4

1×20ˮ

4

765

DN40 PN16

GS-PTFE-5

3×10ˮ

5

186

350

750

300

DN50 PN16

GS-PTFE-10

3×20ˮ

10

1030

DN65 PN16

GS-PTFE-15

4×20ˮ

15

256

440

1115

320

DN80 PN16

GS-PTFE-20

5×20ˮ

20

1130

DN100 PN16

GS-PTFE-30

7×20ˮ

30

GS-PTFE-40

9×20ˮ

40

306

503

1205

350

DN125 PN16

GS-PTFE-50

11×20ˮ

50

356

585

1335

440

GS-PTFE-60

12×20ˮ

60

GS-PTFE-80

15×20ˮ

80

406

630

1380

DN150 PN16

GS-PTFE-100

18×20ˮ

100

GS-PTFE-120

21×20ˮ

120

456

670

1465

DN200 PN16

GS-PTFE-150

24×20ˮ

150

506

730

1550

500

GS-PTFE-180

27×20ˮ

180

1585

DN250 PN16

GS-PTFE-200

30×20ˮ

200

558

790

1640

GS-PTFE-250

36×20ˮ

240

608

910

1780

600

DN300 PN16

GS-PTFE-300

45×20ˮ

300

658

965

1865

650

GS-PTFE-360

60×20ˮ

360

858

1210

2215

820

DN350 PN16

GS-PTFE-400

65×20"

400

2215

DN350 PN16

Note: 1. can be specially designed and processed according to user requirements.

2. . The filtration flux is calculated according to the inlet pressure of 0.2MPa (gauge pressure) and the differential pressure of 0.01MPa. -

Fermentation compressed air filtration system (I)

Air compressor picking filter GS-A type

This series is used for air compressor inlet filtration

Air Master Filter GS-B1

The cartridge is made of folded fiber filter paper or reinforced glass fiber, which has the advantages of large filtration area, small differential pressure, large flow rate and long life.

Air pre-filter GS-B2

Made of ultra-fine glass fiber material with 0.3µm filtration accuracy and up to 95% dust holding space.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Air Fine Filter GS-PTFE

Made of natural strong hydrophobic PTFE membrane and borosilicate microfiber compounded by a special process (Invention Patent No. 03129430.8, 200510024216.2)

Pre