- Products

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

Liquid sterilization filter

所属分类:

Liquid Fine Filter

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Liquid Fine Filter GS-PES/NL/PTFE/PVDF

- Commodity ID: 994905301645615104

Liquid sterilization filter

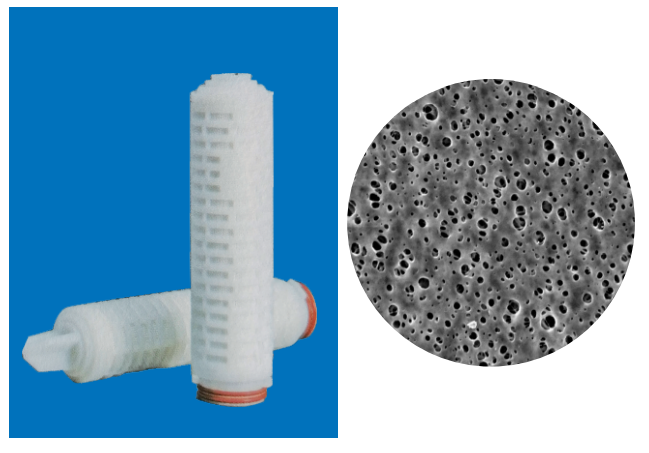

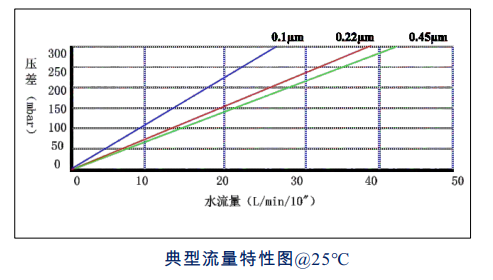

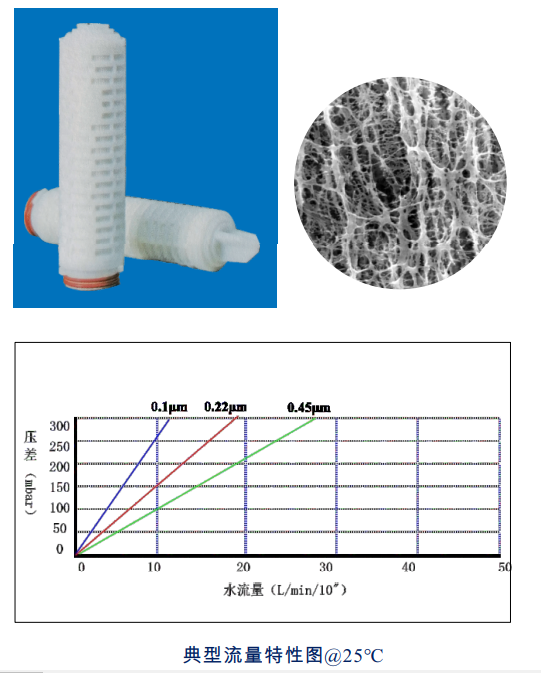

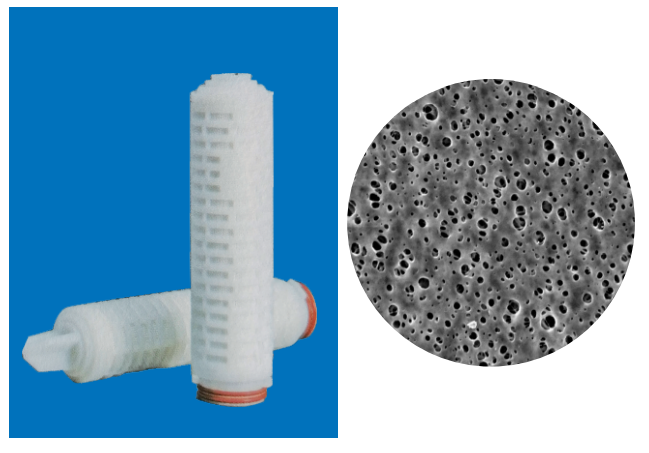

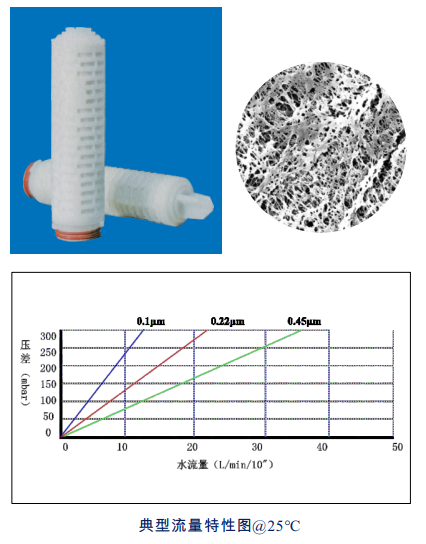

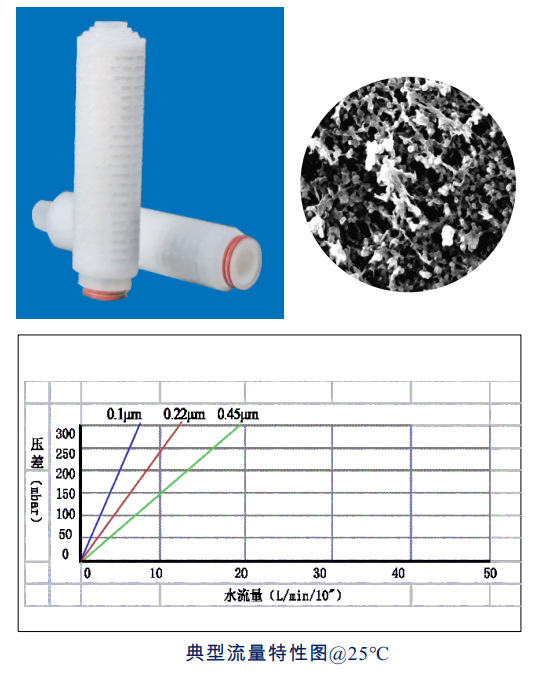

I. High bubble point and low dispersion single-layer polyethersulfone liquid folded cartridge (GS-SPES) seriesGS-SPES series folded cartridge adopts foreign imported asymmetric polyether soar filter membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability, and the good heat resistance of PES can be used for multiple steam sterilization (hot water disinfection), and the 100% integrity test before delivery ensures the safety and reliability of the product, which is widely used in food and beverage industry as well as fermentation supplement, biopharmaceutical, and small molecule chemical generic drug terminal sterilization filtration.Main FeaturesHigh retention rate, good temperature resistance

Wide chemical compatibility, pH working range 1-14

High filtration accuracy, high efficiency of bacterial removal performance

Low protein adsorption, good biosafety, 100% integrity testing, deionized water rinseTypical ApplicationsProcess water and sterile water filtration

Sterilization and filtration of fermentation industry replenishment and antibiotic materials

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of draft beer, wine and yellow wine, sterilization and filtration of glucose syrup

Material StructureFilter material: single layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: single layer hydrophilic polyethersulfone membrane (PES)

Support layer/infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:0.65㎡/10"Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

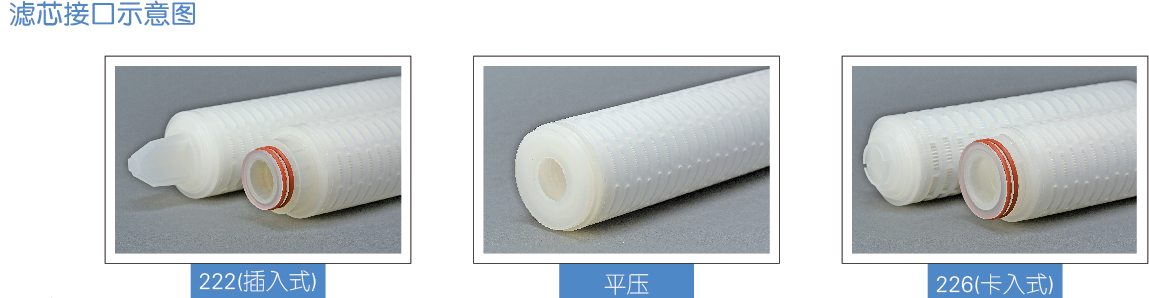

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-SPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

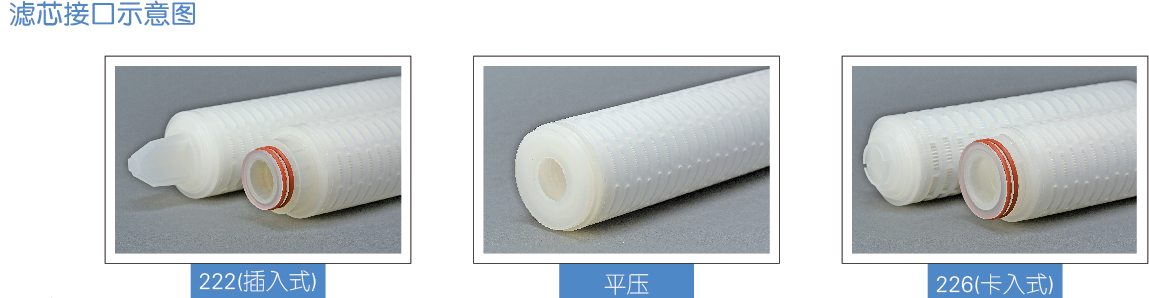

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

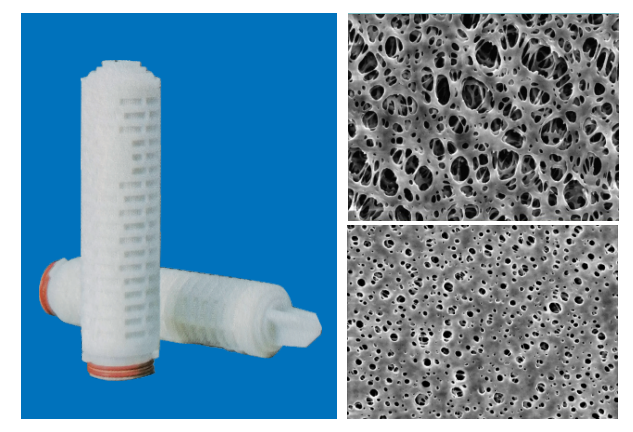

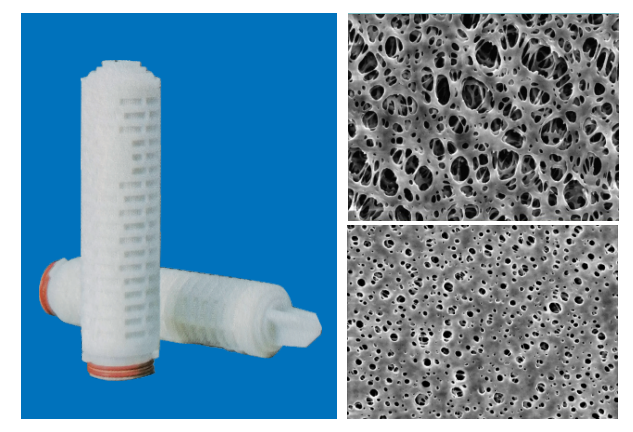

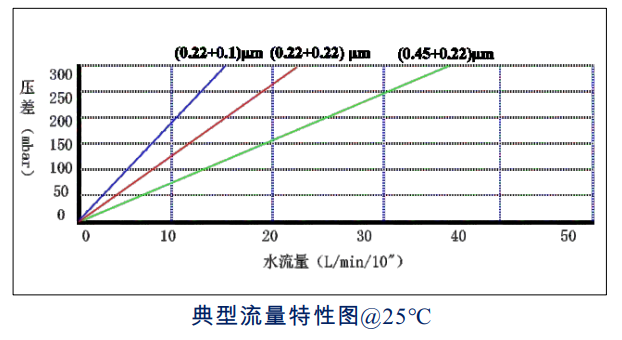

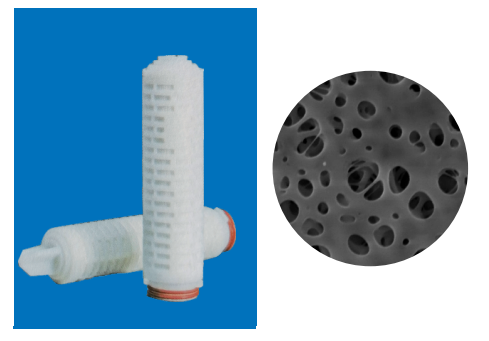

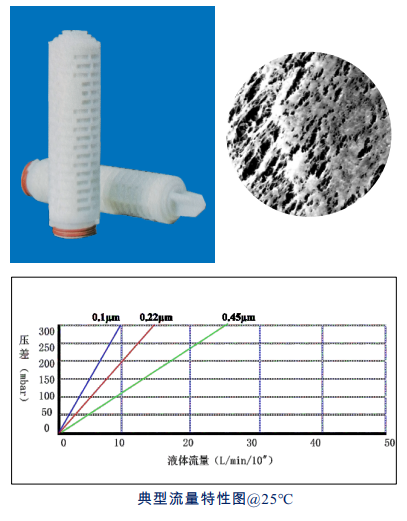

W=Non-sterilizableII. High guarantee and long life double-layer polyethersulfone liquid folding cartridge (GS-DPES) seriesGS-DPES series folded cartridge adopts the combination of foreign imported, asymmetric double-layer membrane polyether alum filter membrane of the same pore size or different pore sizes, which makes it have more reliable bacteria retention capacity and long-life excellent filtration performance with better strength, and can be used for multiple steam sterilization (hot water disinfection), and the 100% integrity test before leaving the factory ensures the safety and reliability of the product, which is widely used in the food and beverage industry as well as the terminal sterilization filtration of fermentation supplement, biopharmaceuticals and small molecule chemical generic drugs.Main FeaturesUnique double-layer combination with higher guaranteed bacterial retention rate

Wide chemical compatibility, pH range 1-14

Robust construction, more disinfection resistance and longer service life

Low protein adsorption, good biosafety

100% integrity testing, deionized water rinseTypical ApplicationsTerminal filtration for fermentation industry replenishment de-sterilization

Sterile filtration of aseptic raw material solution, sterile filtration of fructose syrup

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of pure draft beer, wine and yellow wine

Material StructureFilter material: double-layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: double-layer hydrophilic polyethersulfone membrane (PES)

Support layer/infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

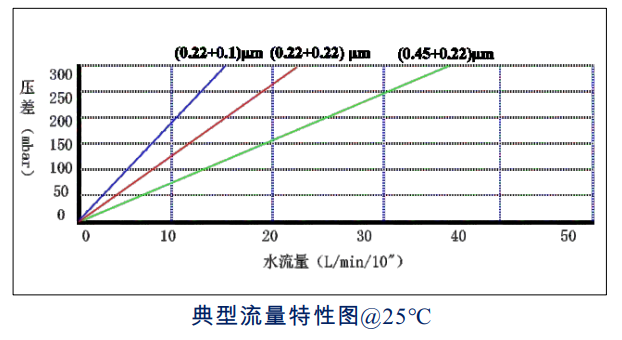

Filtration precision(µm): 0.45+0.22, 0.45+0.45, 0.22+0.22, 0.22+0.1, 0.65+0.45

Effective filtration area: 0.5㎡×2/10"Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-DPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"1022=0.10+0.22µm

2222=0.22+0.22µm

4522=0.45+0.22µm

4545=0.45+0.45µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

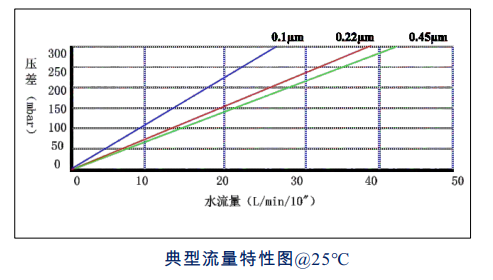

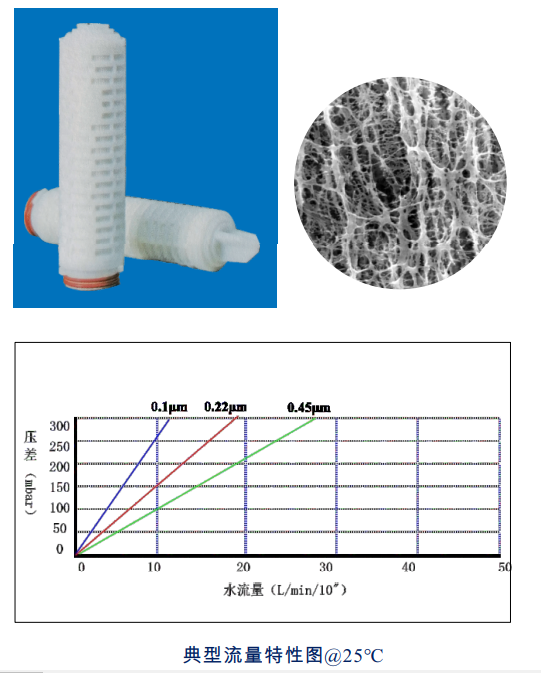

W=Non-sterilizableⅢ、High flux single-layer polyethersulfone liquid folding cartridge (GS-HPES) seriesGS-HPES series folded cartridge adopts foreign imported asymmetric high-throughput polyether alum filter membrane, which is designed by unique structure and has extremely high effective porosity, making it have higher energy. The 100% integrity test before shipment ensures the safety and reliability of the products, which are widely used in the food and beverage industry as well as the terminal sterilization and filtration of fermentation supplement, biopharmaceuticals and small molecule chemical generics.Main FeaturesSpecial support structure for higher filtration capacity

Chemically compatible with a pH range of 1-14

Rugged construction for greater disinfection resistance and longer service life

Low white adsorption, good biosecurity, 100% integrity testing, de-ionization water rinseTypical ApplicationsSterilization end filtration of fermentation industry replenishment, sterile raw material solution sterilization filtration

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of pure beer, wine and liquor, and sterilization and filtration of fructose syrup

Material StructureFilter material: Single-layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: Single-layer hydrophilic polyethersulfone membrane (PES)

Support layer / infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:0.70㎡/10"Operating parametersMaximum working temperature: <90℃

Maximum working pressure difference: forward: 4bar@23℃ 2bar@90℃

Forward: 4bar@23℃ 2bar@90℃

Sterilization method: In-line steam sterilization 123±2℃/30min Hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-HPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

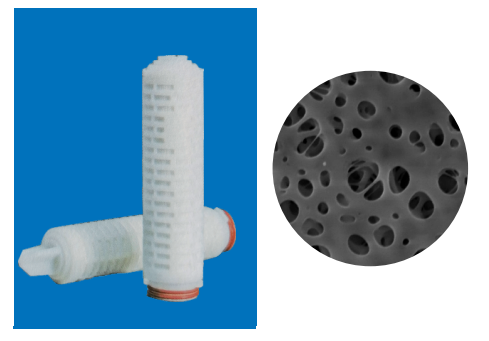

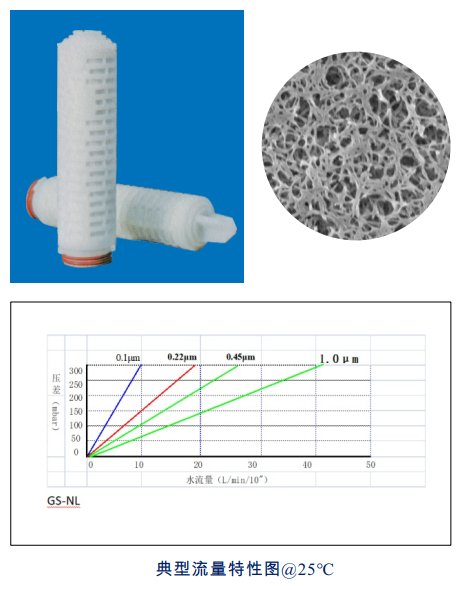

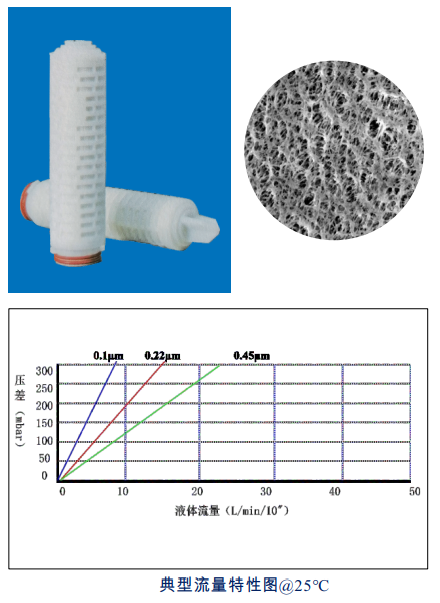

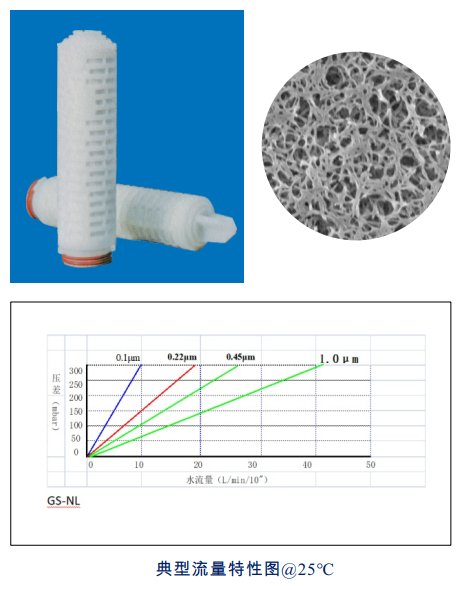

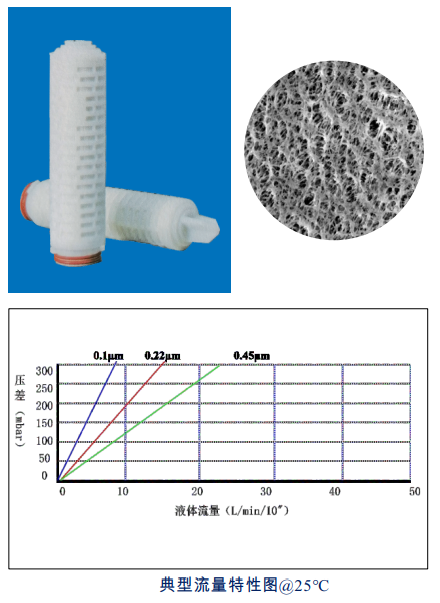

W=Non-sterilizableIV. Natural hydrophilic nylon 6 liquid sterilization cartridge GS-NL seriesGS-NL series folded cartridge adopts natural hydrophilic nylon 6 membrane with independent intellectual property rights and its own technology, which has good hydrophilicity, unique processing technology, high void ratio and uniform distribution of micropores as well as high flux and low precipitates. It is widely used in the purified water, fermentation supplement, food and beverage, and small molecule chemical generic industries to remove impurities, particles, and terminal bacteria filtration.Main FeaturesNatural hydrophilic nylon 6 membrane

Economical and cost-effective sterilization cartridge

Wide chemical compatibility, suitable for alkaline material liquid filtration

Good resistance to organic solvents, 100% integrity testing, deionized water rinsingTypical ApplicationsSterile water filtration, sterilization filtration for the food and beverage industry

Sterilization filtration for fermentation industry make-ups and solvent filtration

Sterilization filtration for large infusion solutions (LVP) and small injections (SVP)Material StructureFilter material: Single layer hydrophilic N6 (NL)

Support layer/Infusion layer: Polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:≥00.65㎡/10" Operating parametersMaximum working temperature: <80℃

Operating parametersMaximum working temperature: <80℃

Max. working pressure difference: forward: 4bar@23℃ 2.4bar@80℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-NL Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

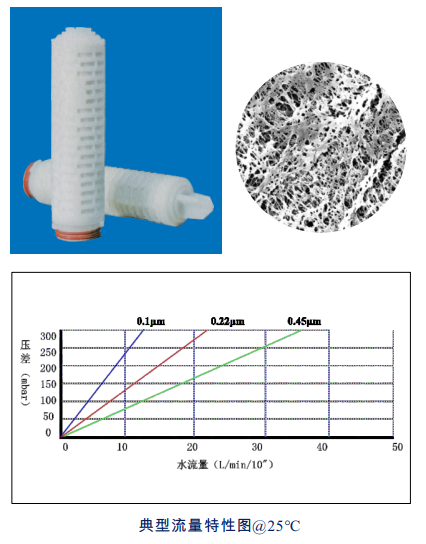

W=Non-sterilizableV. Hydrophilic low resistance high throughput PTFE folded cartridge GS-PTFE QP seriesGS-PTFEQP series cartridge adopts hydrophilic PTFE membrane with stable hydrophilic performance, which can directly filter liquids with water as the main system phase without pre-wetting, and can also filter various corrosive liquids and high temperature liquids. PTFE membrane has organic solvent resistance, oxidation resistance and outstanding corrosion resistance, and GS-PTFEQP series cartridges are available for steam sterilization (hot water disinfection).Main FeaturesHydrophilic Teflon membrane

Wide chemical compatibility, pH working range 1-14

High throughput, long service life

100% integrity testing, deionized water rinseTypical ApplicationsCorrosive liquid filtration, solvent decontamination filtration

Organic solvent filtration

Strong oxidizing liquid filtration, chemical reagent filtrationMaterial StructureFilter material: single layer hydrophilic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: polypropylene or stainless steel

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-HPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableⅥ、Hydrophobic low resistance high-throughput PTFE folded cartridge (GS-PTFE LC) series

GS-PTFELC series folded cartridge adopts biaxially drawn, strongly hydrophobic PTFE membrane with very high porosity, high throughput and low resistance. GS-PTFELC series cartridges are steam sterilizable and 100% integrity testing before delivery ensures the safety and reliability of the products, which are especially suitable for the clarification and filtration of various solvents, corrosive liquids, chemical reagents and strongly oxidizing liquids, as well as sterilization. Filtration.Main FeaturesHydrophobic Teflon membrane

Wide chemical compatibility, pH operating range 1-14 High throughput, long life

100% integrity testingTypical ApplicationsFiltration of corrosive liquids with low surface tension

Disinfection and filtration of solvents and organic solvents

Filtration of strongly oxidizing liquids, filtration of chemical reagentsMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PTFE LC Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableⅦ、Hydrophilic high bubble point low diffusion flow polytetrafluoroethylene folded cartridge (GS-PTFE FP) series

GS-PTFEFP series folded cartridge adopts foreign imported hydrophilic PTFE membrane, which can directly filter the liquid with water as the main system phase without pre-wetting, and can also filter various corrosive liquids and high temperature liquids. 100% integrity test ensures the safety and reliability of the products, especially suitable for clarification and filtration of various solvents, corrosive liquids, chemical reagents and strong oxidizing liquids.

Main FeaturesImported hydrophilic Teflon membrane

Wide chemical compatibility, pH working range 1-14

High throughput and long service life

100% integrity testing, deionized water rinseTypical ApplicationsCorrosive liquid filtration, solvent decontamination filtration

Organic solvent filtration

Strong oxidizing liquid filtration, chemical reagent filtrationMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PTFE FP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tip

T=Fluoroelastomer coatedS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable

W=Non-sterilizableⅧ、Hydrophilic high bubble point low diffusion flow polytetrafluoroethylene folded cartridge (GS-PTFE LF) series

GS-PTFE LF series folded cartridge adopts imported hydrophobic PTFE membrane with very high porosity, high filtration precision, low water immersion value and high flow rate. GS-PTFE LF series cartridges are available for steam sterilization, and the 100% integrity test before delivery ensures the safety and reliability of the products, which are especially suitable for the clarification and filtration of various solvents, corrosive liquids, chemical reagents and strong oxidizing liquids, as well as sterilization. Filtration.Main featuresImported hydrophobic Teflon membrane

Wide chemical compatibility, PH working range 1-14

High throughput and long service life

100% integrity testingTypical ApplicationsFiltration of corrosive liquids with low surface tension

Disinfection and filtration of solvents and organic solvents

Filtration of strong oxidizing liquid, filtration of chemical reagentsMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30minIntegrity testing See the accompanying product quality assurance sheet

Ordering Information

GS-PTFE LF Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tip

T=Fluoroelastomer coatedS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable

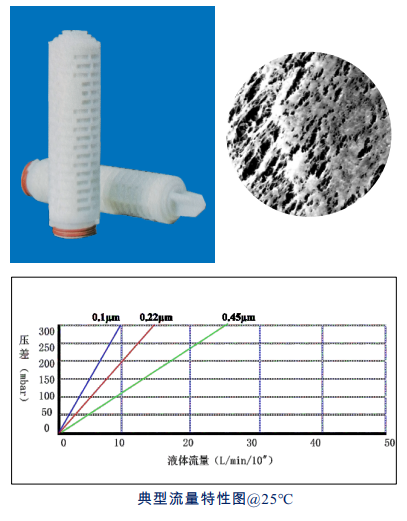

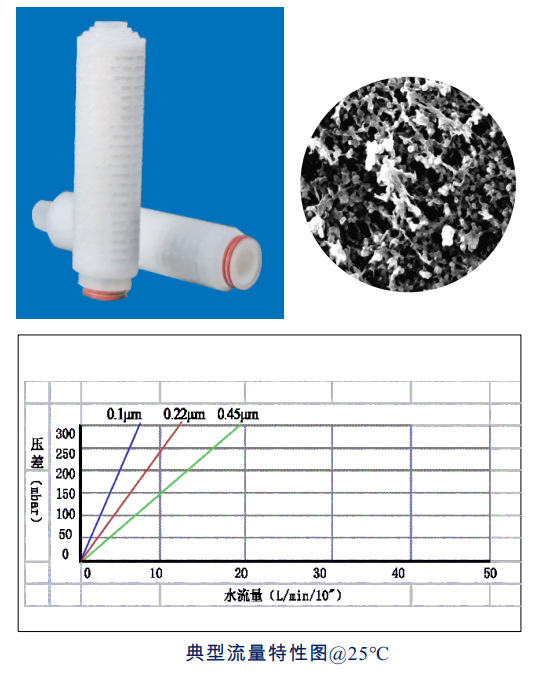

W=Non-sterilizableⅨ、Hydrophilic low protein adsorption polyvinylidene fluoride folded cartridge GS-PVDF seriesGS-PVDF series folded cartridge is made of hydrophilic polyvinylidene fluoride membrane with independent intellectual property rights and its own technology. With stable hydrophilic performance and excellent chemical resistance, it can be filtered directly without pre-wetting, and the PVDF cartridge has extremely low protein adsorption performance, which is especially suitable for sterilization filtration of biological products and filtration of culture fluid and biological reagents, etc. The GS-PVDF cartridge is available for steam sterilization (hot water disinfection), and the 100% integrity test before delivery ensures the safety and reliability of the product.Main featuresHydrophilic polyvinylidene fluoride membranes

Very low protein adsorption properties

Broad chemical compatibility, pH operating range 1-14

100% integrity testing, deionized water rinsingTypical ApplicationsBiological products sterilization filtration

Culture media filtration

Blood product filtration filtration, corrosive liquid filtrationMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PVDF Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizable -

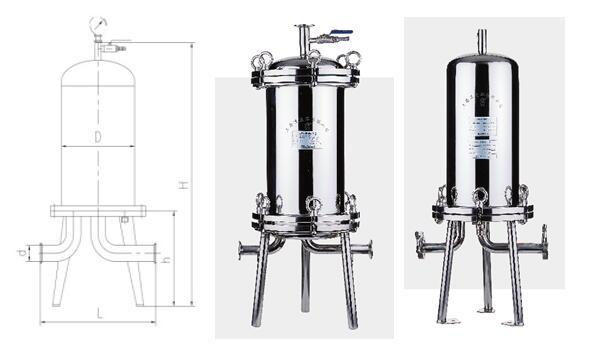

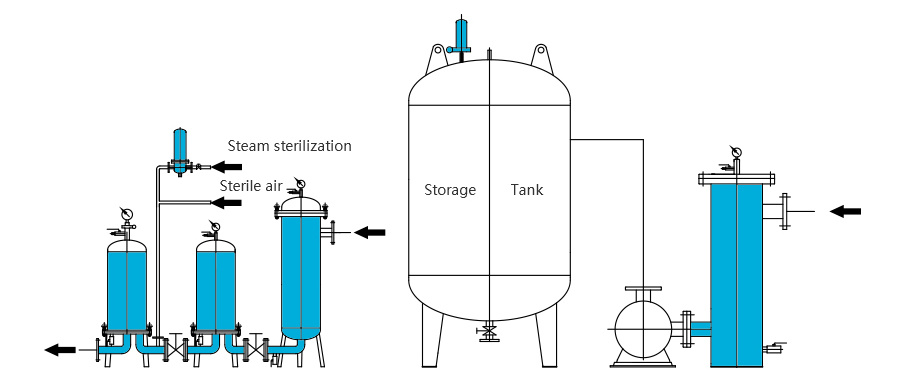

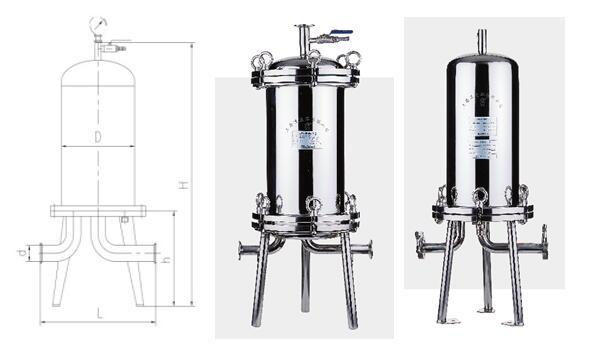

GS type cartridge liquid filters are available in single lower opening, single upper opening, double upper and lower opening, and detachable dismantling type with flower disc base, which can meet the requirements of different filtration processes. The number of filter elements can be configured to meet different filtration flow requirements, and different filter structures can be selected according to different production conditions. All filters are made of sanitary piping and fittings, polished inside and out and pickled and passivated to meet the requirements of sanitary grade. The typical liquid filter has a lower inlet and lower outlet, with less liquid accumulation and the lowest discharge point to prevent contamination.

GS type cartridge filter has the advantages of high filtration efficiency, simple structure and easy installation and replacement of cartridges.

GS series core type liquid filter outline size table

Cartridge configuration Inlet and outlet pipes

DNImport/export connections Overall dimensions

(mm)Length Quantity D

L

H

h

5ˮ

1

15

Quick-fit type

Flange typeФ102

210

455

No legs 10ˮ

20

575

20ˮ

1065

10ˮ

3

25

Ф186

320

730

260

20ˮ

40

980

30ˮ

1230

10ˮ

7

50

Quick-fit type

Flange typeФ256

400

815

295

20ˮ

1065

30ˮ

1315

10ˮ

9

65

Ф306

480

855

325

20ˮ

1105

30ˮ

1355

20ˮ

12

65

Flange type Ф356

540

1145

355

30ˮ

1395

40ˮ

1645

20ˮ

18

80

Ф406

600

1195

385

30ˮ

1445

40ˮ

1695

20ˮ

22

100

Ф456

670

1280

400

30ˮ

1530

40ˮ

1780

20ˮ

27

125

Ф506

720

1325

415

30ˮ

1575

40ˮ

1825

GS type in-line pipe filterThe top inlet and bottom outlet in one compact design, clamped connection, easy disassembly, sanitary piping and fittings, can be used for in-line testing, especially for in-line decontamination filtration or fermenter terminal replenishment decontamination filtration. The housing material is 304 and 316L, and the cartridge material is mainly polyethersulfone, nylon gas 6 and polytetrafluoroethylene. GS-PB type disc filterGS-PB disc membrane filter uses the same centered garden pore filter plate as the pressure support surface for microporous membranes, and can be equipped with various specifications of garden disc type flat membranes as required. The filter is made in accordance with sanitary requirements, and the structure is easy to disassemble and install, with good sealing performance and easy to clean. It can be used for laboratory benchmark tests and is particularly suitable for clarification and sterilization of small quantities of valuable liquids. The housing material is 304 and 316L, and the membrane material is mainly polyvinylidene fluoride, polyethersulfone, and polyethylene oxide 6.

GS-PB type disc filterGS-PB disc membrane filter uses the same centered garden pore filter plate as the pressure support surface for microporous membranes, and can be equipped with various specifications of garden disc type flat membranes as required. The filter is made in accordance with sanitary requirements, and the structure is easy to disassemble and install, with good sealing performance and easy to clean. It can be used for laboratory benchmark tests and is particularly suitable for clarification and sterilization of small quantities of valuable liquids. The housing material is 304 and 316L, and the membrane material is mainly polyvinylidene fluoride, polyethersulfone, and polyethylene oxide 6.

Model Specification Work stress Filter membrane filtration precision Reference pure water flow rate (L/h) GS-PB-Ø100 0.15MPa 0.45µ / 0.22µ 50 GS-PB-Ø150 0.15MPa 0.45µ / 0.22µ 110 GS-PB-Ø200 0.15MPa 0.45µ / 0.22µ 200 GS-PB-Ø300 0.15MPa 0.45µ / 0.22µ 450 -

I. Cartridge ordering information

GS-PES 尺寸 Filtration accuracy Interface Type Seals GS-PTFE 05=5" 010=0.1µm 1=Flat press S=Silicone rubber GS-NL 10=10" 022=0.22µm 2=226 (snap-in) E = EPDM GS-PVDF 20=20" 045=0.45µm 3=222 (inserted) V=Fluoroelastomer 30=30" 1=1.0µm T = fluoroelastomer coated 40=40" Ⅱ、The liquid fine filter design, selectionLiquid fine filter design, selection tableMaterial Basics Material name Flow rate (T/h) Viscosity (centipoise) PH value Name of main solids Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size 304 □

316L □

304 inner wall coating PTFE □

PP □

0.6MPa □

1.0MPa □

Clamps □

Flange □

Pagoda Hose □

Filter element material Filter element filtration precision Filter element interface form Filter element and cartridge sealing ring material Conclusion: Determine the specific model and specification of the filter. Ⅲ、Liquid filter installation steps, liquid filter use precautions, chemical compatibility table(See the "Customer Service/Technical Support" section of our website for details) -

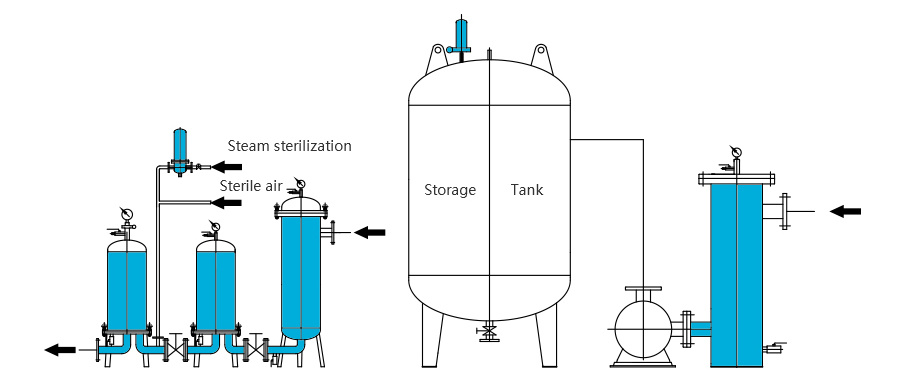

Material removal, clarification, aseptic filtration system

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. When filtering, the liquid flows into the bag from the inlet pipe beside the filter housing, and the bag is supported by a metal mesh basket...

Basket filter GS-LS/LPG, GS-LS/LPGG type

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters, and can also be used for steam filtration in other places.

Sterilization grade air respirator GS-HX type

GS-HX type sterilization air respirator is suitable for installation on the air exchange hole of various types of liquid storage tanks, pure water tanks and sterile dry boxes for sterilization and filtration of gas during gas exchange

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

Liquid sterilization filter

Category:

Liquid Fine Filter

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Liquid Fine Filter GS-PES/NL/PTFE/PVDF

- Commodity ID: 994905301645615104

Liquid sterilization filter

I. High bubble point and low dispersion single-layer polyethersulfone liquid folded cartridge (GS-SPES) seriesGS-SPES series folded cartridge adopts foreign imported asymmetric polyether soar filter membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability, and the good heat resistance of PES can be used for multiple steam sterilization (hot water disinfection), and the 100% integrity test before delivery ensures the safety and reliability of the product, which is widely used in food and beverage industry as well as fermentation supplement, biopharmaceutical, and small molecule chemical generic drug terminal sterilization filtration.Main FeaturesHigh retention rate, good temperature resistance

Wide chemical compatibility, pH working range 1-14

High filtration accuracy, high efficiency of bacterial removal performance

Low protein adsorption, good biosafety, 100% integrity testing, deionized water rinseTypical ApplicationsProcess water and sterile water filtration

Sterilization and filtration of fermentation industry replenishment and antibiotic materials

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of draft beer, wine and yellow wine, sterilization and filtration of glucose syrup

Material StructureFilter material: single layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: single layer hydrophilic polyethersulfone membrane (PES)

Support layer/infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:0.65㎡/10"Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-SPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableII. High guarantee and long life double-layer polyethersulfone liquid folding cartridge (GS-DPES) seriesGS-DPES series folded cartridge adopts the combination of foreign imported, asymmetric double-layer membrane polyether alum filter membrane of the same pore size or different pore sizes, which makes it have more reliable bacteria retention capacity and long-life excellent filtration performance with better strength, and can be used for multiple steam sterilization (hot water disinfection), and the 100% integrity test before leaving the factory ensures the safety and reliability of the product, which is widely used in the food and beverage industry as well as the terminal sterilization filtration of fermentation supplement, biopharmaceuticals and small molecule chemical generic drugs.Main FeaturesUnique double-layer combination with higher guaranteed bacterial retention rate

Wide chemical compatibility, pH range 1-14

Robust construction, more disinfection resistance and longer service life

Low protein adsorption, good biosafety

100% integrity testing, deionized water rinseTypical ApplicationsTerminal filtration for fermentation industry replenishment de-sterilization

Sterile filtration of aseptic raw material solution, sterile filtration of fructose syrup

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of pure draft beer, wine and yellow wine

Material StructureFilter material: double-layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: double-layer hydrophilic polyethersulfone membrane (PES)

Support layer/infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm): 0.45+0.22, 0.45+0.45, 0.22+0.22, 0.22+0.1, 0.65+0.45

Effective filtration area: 0.5㎡×2/10"Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-DPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"1022=0.10+0.22µm

2222=0.22+0.22µm

4522=0.45+0.22µm

4545=0.45+0.45µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableⅢ、High flux single-layer polyethersulfone liquid folding cartridge (GS-HPES) seriesGS-HPES series folded cartridge adopts foreign imported asymmetric high-throughput polyether alum filter membrane, which is designed by unique structure and has extremely high effective porosity, making it have higher energy. The 100% integrity test before shipment ensures the safety and reliability of the products, which are widely used in the food and beverage industry as well as the terminal sterilization and filtration of fermentation supplement, biopharmaceuticals and small molecule chemical generics.Main FeaturesSpecial support structure for higher filtration capacity

Chemically compatible with a pH range of 1-14

Rugged construction for greater disinfection resistance and longer service life

Low white adsorption, good biosecurity, 100% integrity testing, de-ionization water rinseTypical ApplicationsSterilization end filtration of fermentation industry replenishment, sterile raw material solution sterilization filtration

Sterilization and filtration of large infusion solutions (LVP) and small injections (SVP)

Sterilization and filtration of pure beer, wine and liquor, and sterilization and filtration of fructose syrup

Material StructureFilter material: Single-layer hydrophilic polyethersulfone membrane (PES)

Material StructureFilter material: Single-layer hydrophilic polyethersulfone membrane (PES)

Support layer / infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:0.70㎡/10"Operating parametersMaximum working temperature: <90℃

Maximum working pressure difference: forward: 4bar@23℃ 2bar@90℃

Forward: 4bar@23℃ 2bar@90℃

Sterilization method: In-line steam sterilization 123±2℃/30min Hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-HPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableIV. Natural hydrophilic nylon 6 liquid sterilization cartridge GS-NL seriesGS-NL series folded cartridge adopts natural hydrophilic nylon 6 membrane with independent intellectual property rights and its own technology, which has good hydrophilicity, unique processing technology, high void ratio and uniform distribution of micropores as well as high flux and low precipitates. It is widely used in the purified water, fermentation supplement, food and beverage, and small molecule chemical generic industries to remove impurities, particles, and terminal bacteria filtration.Main FeaturesNatural hydrophilic nylon 6 membrane

Economical and cost-effective sterilization cartridge

Wide chemical compatibility, suitable for alkaline material liquid filtration

Good resistance to organic solvents, 100% integrity testing, deionized water rinsingTypical ApplicationsSterile water filtration, sterilization filtration for the food and beverage industry

Sterilization filtration for fermentation industry make-ups and solvent filtration

Sterilization filtration for large infusion solutions (LVP) and small injections (SVP)Material StructureFilter material: Single layer hydrophilic N6 (NL)

Support layer/Infusion layer: Polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision(µm):0.1、0.22、0.45、0.65

Effective filtration area:≥00.65㎡/10" Operating parametersMaximum working temperature: <80℃

Operating parametersMaximum working temperature: <80℃

Max. working pressure difference: forward: 4bar@23℃ 2.4bar@80℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-NL Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableV. Hydrophilic low resistance high throughput PTFE folded cartridge GS-PTFE QP seriesGS-PTFEQP series cartridge adopts hydrophilic PTFE membrane with stable hydrophilic performance, which can directly filter liquids with water as the main system phase without pre-wetting, and can also filter various corrosive liquids and high temperature liquids. PTFE membrane has organic solvent resistance, oxidation resistance and outstanding corrosion resistance, and GS-PTFEQP series cartridges are available for steam sterilization (hot water disinfection).Main FeaturesHydrophilic Teflon membrane

Wide chemical compatibility, pH working range 1-14

High throughput, long service life

100% integrity testing, deionized water rinseTypical ApplicationsCorrosive liquid filtration, solvent decontamination filtration

Organic solvent filtration

Strong oxidizing liquid filtration, chemical reagent filtrationMaterial StructureFilter material: single layer hydrophilic polytetrafluoroethylene membrane (PTFE)

Support layer / infusion layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: polypropylene or stainless steel

O-ring: see cartridge selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-HPES Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableⅥ、Hydrophobic low resistance high-throughput PTFE folded cartridge (GS-PTFE LC) series

GS-PTFELC series folded cartridge adopts biaxially drawn, strongly hydrophobic PTFE membrane with very high porosity, high throughput and low resistance. GS-PTFELC series cartridges are steam sterilizable and 100% integrity testing before delivery ensures the safety and reliability of the products, which are especially suitable for the clarification and filtration of various solvents, corrosive liquids, chemical reagents and strongly oxidizing liquids, as well as sterilization. Filtration.Main FeaturesHydrophobic Teflon membrane

Wide chemical compatibility, pH operating range 1-14 High throughput, long life

100% integrity testingTypical ApplicationsFiltration of corrosive liquids with low surface tension

Disinfection and filtration of solvents and organic solvents

Filtration of strongly oxidizing liquids, filtration of chemical reagentsMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PTFE LC Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizableⅦ、Hydrophilic high bubble point low diffusion flow polytetrafluoroethylene folded cartridge (GS-PTFE FP) series

GS-PTFEFP series folded cartridge adopts foreign imported hydrophilic PTFE membrane, which can directly filter the liquid with water as the main system phase without pre-wetting, and can also filter various corrosive liquids and high temperature liquids. 100% integrity test ensures the safety and reliability of the products, especially suitable for clarification and filtration of various solvents, corrosive liquids, chemical reagents and strong oxidizing liquids.

Main FeaturesImported hydrophilic Teflon membrane

Wide chemical compatibility, pH working range 1-14

High throughput and long service life

100% integrity testing, deionized water rinseTypical ApplicationsCorrosive liquid filtration, solvent decontamination filtration

Organic solvent filtration

Strong oxidizing liquid filtration, chemical reagent filtrationMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PTFE FP Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tip

T=Fluoroelastomer coatedS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable

W=Non-sterilizableⅧ、Hydrophilic high bubble point low diffusion flow polytetrafluoroethylene folded cartridge (GS-PTFE LF) series

GS-PTFE LF series folded cartridge adopts imported hydrophobic PTFE membrane with very high porosity, high filtration precision, low water immersion value and high flow rate. GS-PTFE LF series cartridges are available for steam sterilization, and the 100% integrity test before delivery ensures the safety and reliability of the products, which are especially suitable for the clarification and filtration of various solvents, corrosive liquids, chemical reagents and strong oxidizing liquids, as well as sterilization. Filtration.Main featuresImported hydrophobic Teflon membrane

Wide chemical compatibility, PH working range 1-14

High throughput and long service life

100% integrity testingTypical ApplicationsFiltration of corrosive liquids with low surface tension

Disinfection and filtration of solvents and organic solvents

Filtration of strong oxidizing liquid, filtration of chemical reagentsMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30minIntegrity testing See the accompanying product quality assurance sheet

Ordering Information

GS-PTFE LF Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tip

T=Fluoroelastomer coatedS=Silicone rubber

E=Ethylene-Propylene

V=FluoroelastomerR = sterilizable

W=Non-sterilizableⅨ、Hydrophilic low protein adsorption polyvinylidene fluoride folded cartridge GS-PVDF seriesGS-PVDF series folded cartridge is made of hydrophilic polyvinylidene fluoride membrane with independent intellectual property rights and its own technology. With stable hydrophilic performance and excellent chemical resistance, it can be filtered directly without pre-wetting, and the PVDF cartridge has extremely low protein adsorption performance, which is especially suitable for sterilization filtration of biological products and filtration of culture fluid and biological reagents, etc. The GS-PVDF cartridge is available for steam sterilization (hot water disinfection), and the 100% integrity test before delivery ensures the safety and reliability of the product.Main featuresHydrophilic polyvinylidene fluoride membranes

Very low protein adsorption properties

Broad chemical compatibility, pH operating range 1-14

100% integrity testing, deionized water rinsingTypical ApplicationsBiological products sterilization filtration

Culture media filtration

Blood product filtration filtration, corrosive liquid filtrationMaterial StructureFilter material: single layer hydrophobic polytetrafluoroethylene membrane (PTFE)

Support layer/fluid guide layer: polypropylene

Housing/end caps/fins: polypropylene

Center tube: stainless steel or polypropylene

O-ring: see cartridge selection table

Sealing technology: adhesive-free heat seal technologyCartridge parametersOuter diameter:Φ68.5

Length: 5", 10", 20", 30", 40"

Filtration precision (µm):0.22, 0.45, 1.0

Effective filtration area:0.65㎡/10" Operating parametersMaximum working temperature: <90℃

Operating parametersMaximum working temperature: <90℃

Max. working pressure difference: forward: 4bar@23℃ 2bar@90℃

Reverse: 2bar@23℃

Sterilization mode: online steam sterilization 123±2℃/30min hot water 85℃/60minIntegrity testing See the accompanying product quality assurance sheetOrdering InformationGS-PVDF Size Filtration accuracy Lower Interface Upper Interface Seals Type of disinfection 05=5"

10=10"

20=20"

30=30"

40=40"0010=0.10µm

0022=0.22µm

0045=0.45µm

0065=0.65µm1=Flat press

2=226(regular)

3=222(Regular)

6=222(steel lined ring)

7=226(steel lined ring)P=Plat

T=Triangular fins

C=columnar fin tipS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerR = sterilizable

W=Non-sterilizable -

GS type cartridge liquid filters are available in single lower opening, single upper opening, double upper and lower opening, and detachable dismantling type with flower disc base, which can meet the requirements of different filtration processes. The number of filter elements can be configured to meet different filtration flow requirements, and different filter structures can be selected according to different production conditions. All filters are made of sanitary piping and fittings, polished inside and out and pickled and passivated to meet the requirements of sanitary grade. The typical liquid filter has a lower inlet and lower outlet, with less liquid accumulation and the lowest discharge point to prevent contamination.

GS type cartridge filter has the advantages of high filtration efficiency, simple structure and easy installation and replacement of cartridges.

GS series core type liquid filter outline size table

Cartridge configuration Inlet and outlet pipes

DNImport/export connections Overall dimensions

(mm)Length Quantity D

L

H

h

5ˮ

1

15

Quick-fit type

Flange typeФ102

210

455

No legs 10ˮ

20

575

20ˮ

1065

10ˮ

3

25

Ф186

320

730

260

20ˮ

40

980

30ˮ

1230

10ˮ

7

50

Quick-fit type

Flange typeФ256

400

815

295

20ˮ

1065

30ˮ

1315

10ˮ

9

65

Ф306

480

855

325

20ˮ

1105

30ˮ

1355

20ˮ

12

65

Flange type Ф356

540

1145

355

30ˮ

1395

40ˮ

1645

20ˮ

18

80

Ф406

600

1195

385

30ˮ

1445

40ˮ

1695

20ˮ

22

100

Ф456

670

1280

400

30ˮ

1530

40ˮ

1780

20ˮ

27

125

Ф506

720

1325

415

30ˮ

1575

40ˮ

1825

GS type in-line pipe filterThe top inlet and bottom outlet in one compact design, clamped connection, easy disassembly, sanitary piping and fittings, can be used for in-line testing, especially for in-line decontamination filtration or fermenter terminal replenishment decontamination filtration. The housing material is 304 and 316L, and the cartridge material is mainly polyethersulfone, nylon gas 6 and polytetrafluoroethylene. GS-PB type disc filterGS-PB disc membrane filter uses the same centered garden pore filter plate as the pressure support surface for microporous membranes, and can be equipped with various specifications of garden disc type flat membranes as required. The filter is made in accordance with sanitary requirements, and the structure is easy to disassemble and install, with good sealing performance and easy to clean. It can be used for laboratory benchmark tests and is particularly suitable for clarification and sterilization of small quantities of valuable liquids. The housing material is 304 and 316L, and the membrane material is mainly polyvinylidene fluoride, polyethersulfone, and polyethylene oxide 6.

GS-PB type disc filterGS-PB disc membrane filter uses the same centered garden pore filter plate as the pressure support surface for microporous membranes, and can be equipped with various specifications of garden disc type flat membranes as required. The filter is made in accordance with sanitary requirements, and the structure is easy to disassemble and install, with good sealing performance and easy to clean. It can be used for laboratory benchmark tests and is particularly suitable for clarification and sterilization of small quantities of valuable liquids. The housing material is 304 and 316L, and the membrane material is mainly polyvinylidene fluoride, polyethersulfone, and polyethylene oxide 6.

Model Specification Work stress Filter membrane filtration precision Reference pure water flow rate (L/h) GS-PB-Ø100 0.15MPa 0.45µ / 0.22µ 50 GS-PB-Ø150 0.15MPa 0.45µ / 0.22µ 110 GS-PB-Ø200 0.15MPa 0.45µ / 0.22µ 200 GS-PB-Ø300 0.15MPa 0.45µ / 0.22µ 450 -

I. Cartridge ordering information

GS-PES 尺寸 Filtration accuracy Interface Type Seals GS-PTFE 05=5" 010=0.1µm 1=Flat press S=Silicone rubber GS-NL 10=10" 022=0.22µm 2=226 (snap-in) E = EPDM GS-PVDF 20=20" 045=0.45µm 3=222 (inserted) V=Fluoroelastomer 30=30" 1=1.0µm T = fluoroelastomer coated 40=40" Ⅱ、The liquid fine filter design, selectionLiquid fine filter design, selection tableMaterial Basics Material name Flow rate (T/h) Viscosity (centipoise) PH value Name of main solids Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size 304 □

316L □

304 inner wall coating PTFE □

PP □

0.6MPa □

1.0MPa □

Clamps □

Flange □

Pagoda Hose □

Filter element material Filter element filtration precision Filter element interface form Filter element and cartridge sealing ring material Conclusion: Determine the specific model and specification of the filter. Ⅲ、Liquid filter installation steps, liquid filter use precautions, chemical compatibility table(See the "Customer Service/Technical Support" section of our website for details) -

Material removal, clarification, aseptic filtration system

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. When filtering, the liquid flows into the bag from the inlet pipe beside the filter housing, and the bag is supported by a metal mesh basket...

Basket filter GS-LS/LPG, GS-LS/LPGG type

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters, and can also be used for steam filtration in other places.

Sterilization grade air respirator GS-HX type

GS-HX type sterilization air respirator is suitable for installation on the air exchange hole of various types of liquid storage tanks, pure water tanks and sterile dry boxes for sterilization and filtration of gas during gas exchange

Pre