- Products

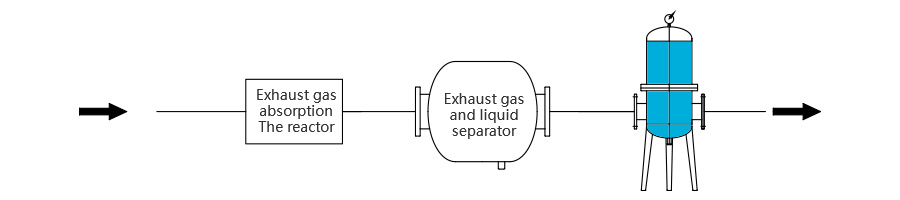

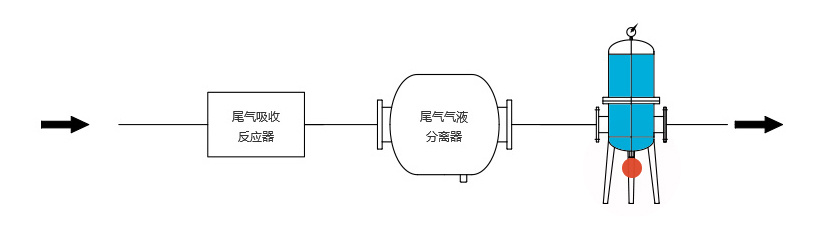

Fermentation exhaust secondary treatment and filtration system (absorption and odor removal, bacteria removal)

With the country's increasingly strict requirements for environmental protection, seed tanks, fermentation tanks in the production process of exhaust gas produced by enterprises can not be discharged at will, can not form odor pollution (odor pollution than fermentation wastewater discharge is more likely to cause complaints from the surrounding residents), coupled with the fact that some fermentation with genetically engineered bacteria, live bacteria can not be discharged into the atmosphere with the exhaust gas at will, which requires fermentation enterprises need to fermentation exhaust gas for This requires fermentation enterprises to centralize the treatment of fermentation exhaust gas before it can be discharged into the atmosphere. There are professional environmental protection companies in the market to deal with fermentation exhaust gas, such as absorption, deodorization, etc. Here we just talk about the fermentation exhaust gas filtration initially.

"Fermentation exhaust gas filtration and de-bacterization" in the laboratory or pilot level fermentation tanks have been more widely and successfully used, most of these fermentation tanks are below 300L, very few reach about 2000L, compared to the large production of hundreds of cubic meters of fermentation tank tank capacity, these limited use, whether it has the value of promotion is still It is not known, at least the domestic has not been successfully used on a few hundred cubic meters tank reports. Mainly there are two major technical difficulties to be tackled, one is the high humidity of the fermentation exhaust gas, bacteria removal cartridge filter membrane is easy to form a "water film" resulting in a sharp decline in permeability, easy to produce fermentation "hold tank" or "high CO2 concentration, CO2 poisoning", thus affecting production. CO2 poisoning", thus affecting the production; secondly, the power of filtration is not enough, the pressure of the tail gas filter comes from the tank pressure, generally the antibiotic fermentation tank pressure is within 0.025MPa, the amino acid fermentation tank pressure is a little higher at about 0.05MPa, these two pressures are not enough power for the sterilization level filter.

In November 2017, our company designed and provided 8 sets of "tail gas filters" on 500 cubic meters fermentation tanks in the amino acid fermentation project of a company in the northeast, and in response to the above two technical difficulties, our technical staff innovatively improved the combination of the filter membrane of the sterilization cartridge, optimized the design of the filter shell, and cooperated with the owner. Optimize the installation direction of exhaust gas discharge pipe. Since the project has not yet been put into production use, the specific effect will not be known until after it is put into use. Regardless of the effect of future use, our company believes that such an attempt is still meaningful, to use a popular phrase: maybe, accidentally, the ideal will come true!

Exhaust emission de-bacterization filter (optional)

"Fermentation exhaust gas filtration and de-bacterization" has been widely and successfully used in laboratory or pilot-scale fermenters

Exhaust emission de-bacterization filter (optional)

"Fermentation exhaust gas filtration and de-bacterization" has been widely and successfully used in laboratory or pilot-scale fermenters