- Products

Water removal filter GS-E9/C type

除水过滤器GS-E9/C型

所属分类:

Water removal filter GS-E9/C type

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Water removal filter GS-E9/C type

- Commodity ID: 994906079181496320

除水过滤器GS-E9/C型

Suitable for filtering out large amount of liquid and 3μm size coalescence to 5ppmw/w maximum residual oil content. Two-stage filtration: Stage 1 Two stainless steel pipe bores for 10μm mechanical separation; Stage 2 Deep fiber media to filter out 3μm solid and liquid particles.

Model Flow

(NM3/min)

E9/C-12

0.57

E9/C-16

1

E9/C-20

1.72

E9/C-24

2.9

E9/C-28

4.9

E9/C-32

7.2

E9/C-36

10.7

E9/C-40

14

E9/C-44

17.7

E9/C-48

22

Note: Our company can provide equivalent replacement products for imported cartridges, such as Hankison, Parker, Domnick Hunter, Atlas Copco, Ingersoll Rand, SMC series.

(Domnick Hunter), Atlas (Atlas Copco), Ingersoll Rand, SMC series. etc. -

The shell is made of high quality aluminum alloy and carbon steel, and the maximum pressure can be up to 16 kg; the inside and outside of the shell adopt advanced surface treatment technology, with high durability and corrosion resistance and long service life; the air flow direction is marked on the shell, which is easy to use and install; the special differential pressure gauge indicates the best time to replace the cartridge, so that the cartridge has a higher utilization rate in the state of lowest pressure drop; the automatic drainage device (optional) adopts indirect drainage type, which ensures smooth water release, no blockage and reliable and durable.

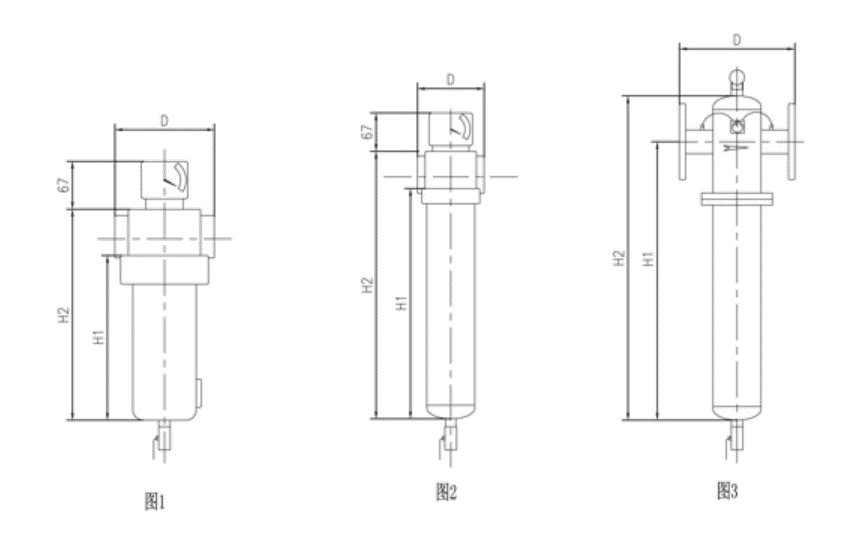

Filter Model Nominal flow rate Interface Size Cartridge type and quantity Dimension(mm) Refer to the illustration D

H1

H2

Figure number GS-E9/C-12

0.57

1/2"

E9/C-12 1pc 104

217

243

Figure 1 GS-E9/C-16

1

1/2"

E9/C-16 1 pc

104

217

243

Figure 1 GS-E9/C-20

1.72

1 1/2"

E9/C-20 1 pc

104

287

313

Figure 1 GS-E9/C-24

2.9

1 1/2"

E9/C-24 1 pc

138

385

424

Figure 1 GS-E9/C-28

4.9

1 1/2"

E9/C-28 1 pc

138

385

424

Figure 1 GS-E9/C-32

7.2

1 1/2"

E9/C-32 1 pc

138

585

624

Figure 1 GS-E9/C-36

10.7

2"

E9/C-36 1 pc

148

639

685

Figure 2 GS-E9/C-40

14

2"

E9/C-40 1 pc

148

639

685

Figure 2 GS-E9/C-44

17.7

PN16DN65

E9/C-44 1 pc

300(Ø133)

770

940

Figure 3 GS-E9/C-48

22

PN16DN80

E9/C-48 1 pc

336(Ø159)

943

1118

Figure 3 GS-E9/C-56

36

PN16DN100

E9/C-44 2 pc

500(Ø219)

990

1250

Figure 3 GS-E9/C-60

54

PN16DN100

E9/C-44 3 pc

500(Ø273)

990

1250

Figure 3 GS-E9/C-64

72

PN16DN100

E9/C-44 4 pc

600(Ø377)

990

1250

Figure 3 GS-E9/C-68

90

PN16DN125

E9/C-44 5 pc

600(Ø377)

1050

1250

Figure 3 -

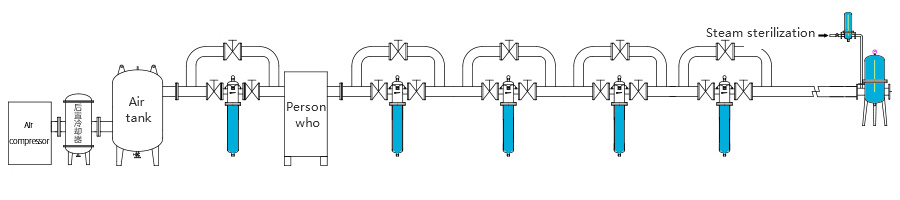

Compressed air precision filter installation location.

The water removal filter GS-E9/C is used after the rear cooler of the air compressor, before the cold dryer, and before other filters for general protection.Compressed air precision filter notes.

1、Filters are configured with the principle of "E9, E7, E5, E3, E1, coarse first, then fine", and the order cannot be reversed.

2, the actual compressed air flow, pressure and temperature through the filter should not exceed the value specified in the nameplate.

3, installation must pay attention to distinguish the filter inlet and outlet position.

4, the filter installation should be vertical to the ground. Leave a certain height from the ground to facilitate the exchange of filter elements.

5、The filter element should be replaced when one of the following conditions occurs.

a. The filtering effect deteriorates significantly;

b. Differential pressure indicates a value of more than 0.07MPa (Note: the initial pressure drop of the cartridge <0.015Mpa).

c. GS-E9/C cartridge use time limit: more than 8000h.

6. For the filter without automatic drain (please specifically state when ordering for automatic drain), the ball valve should be opened regularly to remove the water accumulated in the filter shell. Usually not less than 1-2 times per shift.

7、Filter inlet air temperature should not exceed 66℃.

8、If the working pressure is lower than the standard value (0.7MPa), the actual filtering capacity of the filter will be corrected according to the following table.Inlet pressure (MPa) 0.15

0.35

0.5

0.7

0.9

1.05

Correction factor 0.25

0.5

0.75

1.0

1.24

1.43

Common troubleshooting of compressed air precision filters.

If the filter malfunctions during use, please find out the causes as described below, and then deal with them at the right time.

(a) "The flow rate decreases and fails to meet the actual production requirements" may be caused as follows.

1、The filter end cover is not closed tightly or the filter shell is leaking.

2, import and export valves are not fully open.

3, O-ring seal deteriorates, resulting in air leakage.

4, the inlet pressure is too low.

(2) "Large pressure drop, the flow rate does not meet the actual production requirements" may be due to the following reasons.

1, cartridge use time exceeds the limit or blockage.

2, inlet air impurities, load is too heavy.

3, drainage failure, too much water in the filter shell.

4、The filter selection is small and the processing flow exceeds the rated value of the filter.

5, the filter import and export connected to the reverse.

(C) "Poor filtration effect, not up to the actual production of air quality requirements" may be due to the following reasons.

1、The order of filter installation is reversed.

2, the upstream pipeline is not clean or the inlet air source is not necessary pretreatment, resulting in filter element contamination.

3、The bypass service valve is not closed tightly.

4、The air contains harmful substances.

5、The use time of the filter element exceeds the limit or the airflow inside the filter is short-circuited. -

Fermentation compressed air filtration system (II)

Water removal filter GS-E9/C

Suitable for filtering out large amounts of liquids and 3μm size coalescents to 5ppm w/w maximum residual oil content.

Dust filter GS-E7/T

It is suitable for filtering out liquid water and oil, and can filter out solid particles as small as 1μm and reach 1.0ppm w/w maximum residual oil content.

High efficiency oil mist removal filter GS-E5/A type

Suitable for agglomeration of very fine water vapor and oil mist, can filter out solid particles as small as 0.01μm...

Super high efficiency oil mist filter GS-E3/F type

Suitable for agglomerating very fine water vapor and oil mist, filtering out solid particles as small as 0.01μm to achieve 0.001ppm w/w maximum residual oil content.

Deodorizing activated carbon filter GS-E1/H type

Suitable for filtering out oil vapors and hydrocarbon vapors normally absorbed by activated carbon, and for filtering out solid particles down to 0.01μm

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Air sterilization grade filter GS-PTFE type

GS-PTFE HP series cartridge is made of natural strong hydrophobic PTFE membrane (double-layer membrane)

Water removal filter GS-E9/C type

除水过滤器GS-E9/C型

Category:

Water removal filter GS-E9/C type

- Cartridge

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Water removal filter GS-E9/C type

- Commodity ID: 994906079181496320

除水过滤器GS-E9/C型

Suitable for filtering out large amount of liquid and 3μm size coalescence to 5ppmw/w maximum residual oil content. Two-stage filtration: Stage 1 Two stainless steel pipe bores for 10μm mechanical separation; Stage 2 Deep fiber media to filter out 3μm solid and liquid particles.

Model Flow

(NM3/min)

E9/C-12

0.57

E9/C-16

1

E9/C-20

1.72

E9/C-24

2.9

E9/C-28

4.9

E9/C-32

7.2

E9/C-36

10.7

E9/C-40

14

E9/C-44

17.7

E9/C-48

22

Note: Our company can provide equivalent replacement products for imported cartridges, such as Hankison, Parker, Domnick Hunter, Atlas Copco, Ingersoll Rand, SMC series.

(Domnick Hunter), Atlas (Atlas Copco), Ingersoll Rand, SMC series. etc. -

The shell is made of high quality aluminum alloy and carbon steel, and the maximum pressure can be up to 16 kg; the inside and outside of the shell adopt advanced surface treatment technology, with high durability and corrosion resistance and long service life; the air flow direction is marked on the shell, which is easy to use and install; the special differential pressure gauge indicates the best time to replace the cartridge, so that the cartridge has a higher utilization rate in the state of lowest pressure drop; the automatic drainage device (optional) adopts indirect drainage type, which ensures smooth water release, no blockage and reliable and durable.

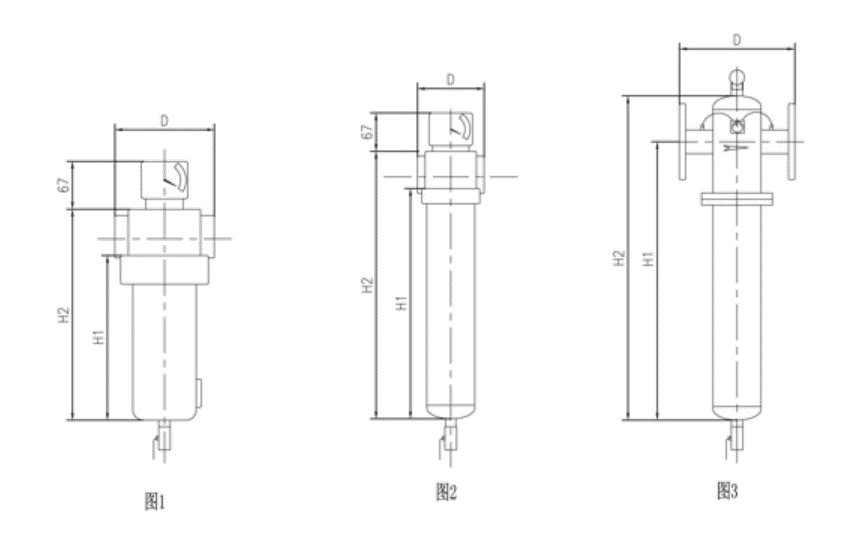

Filter Model Nominal flow rate Interface Size Cartridge type and quantity Dimension(mm) Refer to the illustration D

H1

H2

Figure number GS-E9/C-12

0.57

1/2"

E9/C-12 1pc 104

217

243

Figure 1 GS-E9/C-16

1

1/2"

E9/C-16 1 pc

104

217

243

Figure 1 GS-E9/C-20

1.72

1 1/2"

E9/C-20 1 pc

104

287

313

Figure 1 GS-E9/C-24

2.9

1 1/2"

E9/C-24 1 pc

138

385

424

Figure 1 GS-E9/C-28

4.9

1 1/2"

E9/C-28 1 pc

138

385

424

Figure 1 GS-E9/C-32

7.2

1 1/2"

E9/C-32 1 pc

138

585

624

Figure 1 GS-E9/C-36

10.7

2"

E9/C-36 1 pc

148

639

685

Figure 2 GS-E9/C-40

14

2"

E9/C-40 1 pc

148

639

685

Figure 2 GS-E9/C-44

17.7

PN16DN65

E9/C-44 1 pc

300(Ø133)

770

940

Figure 3 GS-E9/C-48

22

PN16DN80

E9/C-48 1 pc

336(Ø159)

943

1118

Figure 3 GS-E9/C-56

36

PN16DN100

E9/C-44 2 pc

500(Ø219)

990

1250

Figure 3 GS-E9/C-60

54

PN16DN100

E9/C-44 3 pc

500(Ø273)

990

1250

Figure 3 GS-E9/C-64

72

PN16DN100

E9/C-44 4 pc

600(Ø377)

990

1250

Figure 3 GS-E9/C-68

90

PN16DN125

E9/C-44 5 pc

600(Ø377)

1050

1250

Figure 3 -

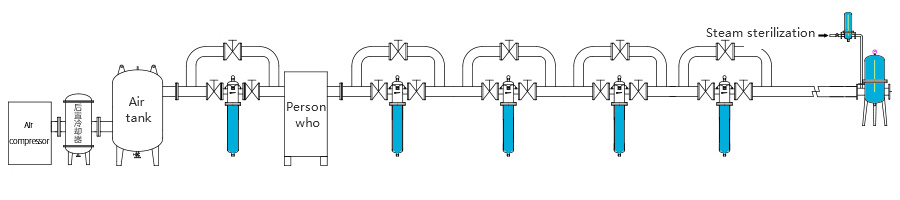

Compressed air precision filter installation location.

The water removal filter GS-E9/C is used after the rear cooler of the air compressor, before the cold dryer, and before other filters for general protection.Compressed air precision filter notes.

1、Filters are configured with the principle of "E9, E7, E5, E3, E1, coarse first, then fine", and the order cannot be reversed.

2, the actual compressed air flow, pressure and temperature through the filter should not exceed the value specified in the nameplate.

3, installation must pay attention to distinguish the filter inlet and outlet position.

4, the filter installation should be vertical to the ground. Leave a certain height from the ground to facilitate the exchange of filter elements.

5、The filter element should be replaced when one of the following conditions occurs.

a. The filtering effect deteriorates significantly;

b. Differential pressure indicates a value of more than 0.07MPa (Note: the initial pressure drop of the cartridge <0.015Mpa).

c. GS-E9/C cartridge use time limit: more than 8000h.

6. For the filter without automatic drain (please specifically state when ordering for automatic drain), the ball valve should be opened regularly to remove the water accumulated in the filter shell. Usually not less than 1-2 times per shift.

7、Filter inlet air temperature should not exceed 66℃.

8、If the working pressure is lower than the standard value (0.7MPa), the actual filtering capacity of the filter will be corrected according to the following table.Inlet pressure (MPa) 0.15

0.35

0.5

0.7

0.9

1.05

Correction factor 0.25

0.5

0.75

1.0

1.24

1.43

Common troubleshooting of compressed air precision filters.

If the filter malfunctions during use, please find out the causes as described below, and then deal with them at the right time.

(a) "The flow rate decreases and fails to meet the actual production requirements" may be caused as follows.

1、The filter end cover is not closed tightly or the filter shell is leaking.

2, import and export valves are not fully open.

3, O-ring seal deteriorates, resulting in air leakage.

4, the inlet pressure is too low.

(2) "Large pressure drop, the flow rate does not meet the actual production requirements" may be due to the following reasons.

1, cartridge use time exceeds the limit or blockage.

2, inlet air impurities, load is too heavy.

3, drainage failure, too much water in the filter shell.

4、The filter selection is small and the processing flow exceeds the rated value of the filter.

5, the filter import and export connected to the reverse.

(C) "Poor filtration effect, not up to the actual production of air quality requirements" may be due to the following reasons.

1、The order of filter installation is reversed.

2, the upstream pipeline is not clean or the inlet air source is not necessary pretreatment, resulting in filter element contamination.

3、The bypass service valve is not closed tightly.

4、The air contains harmful substances.

5、The use time of the filter element exceeds the limit or the airflow inside the filter is short-circuited. -

Fermentation compressed air filtration system (II)

Water removal filter GS-E9/C

Suitable for filtering out large amounts of liquids and 3μm size coalescents to 5ppm w/w maximum residual oil content.

Dust filter GS-E7/T

It is suitable for filtering out liquid water and oil, and can filter out solid particles as small as 1μm and reach 1.0ppm w/w maximum residual oil content.

High efficiency oil mist removal filter GS-E5/A type

Suitable for agglomeration of very fine water vapor and oil mist, can filter out solid particles as small as 0.01μm...

Super high efficiency oil mist filter GS-E3/F type

Suitable for agglomerating very fine water vapor and oil mist, filtering out solid particles as small as 0.01μm to achieve 0.001ppm w/w maximum residual oil content.

Deodorizing activated carbon filter GS-E1/H type

Suitable for filtering out oil vapors and hydrocarbon vapors normally absorbed by activated carbon, and for filtering out solid particles down to 0.01μm

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Air sterilization grade filter GS-PTFE type

GS-PTFE HP series cartridge is made of natural strong hydrophobic PTFE membrane (double-layer membrane)

Pre