- Products

Bag filter GS-DS type

Bag filter GS-DS type

所属分类:

Bag filter GS-DS type

- Description

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Bag filter GS-DS type

- Commodity ID: 994905625676570624

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a very wide range of applications. When filtering, the liquid flows into the filter bag from the inlet tube beside the filter housing, the bag is supported by a metal mesh basket, the liquid penetrates the filter bag through the bottom outlet tube and flows out of the filtration system, the impurity particles are intercepted in the filter bag, and the cleaning or replacement of the filter bag can continue to use. Bag filter has simple structure, easy operation, large flow rate and low pressure difference, etc. It is widely used in biochemical, antibiotic, amino acid, beer, beverage and functional sugar industries.

GS-DS type bag filter bag specifications are 1# bag-5# bag, suitable for different flow rate filtration needs, filter bag materials mainly include polypropylene PP (general-purpose), polyester PET (high temperature and solvent resistance) and nylon NL monofilament screen (large aperture high flux high temperature resistance), filtration accuracy range 0.5 ~ 500µm, suitable for the filtration of different characteristics of the material liquid. The sealing ring has stainless steel ring and plastic ring.

Polypropylene PP filter bag: polypropylene needle felt filter bag belongs to the deep filtration, three-dimensional three-dimensional loose pore formed by the fiber, the surface after rolling light, burnt wool and other processes, no fiber off, to prevent secondary pollution; does not contain silicone oil, no chemical release; filter material from inside and outside from loose to dense, forming a gradient filtration, can provide liquid flow and impurity dirt-holding capacity, for all types of soft impurities have a superb Filtration effect, PH value tolerance wide 1-14, filtration precision range: 0.1250 micron; working temperature should be controlled within 90 ℃. Filter bag processing technology has a bag body wire sewing bag mouth steel ring, bag body hot welding bag mouth plastic ring two.

Polyester PET filter bag: polyester needle felt filter bag belongs to the deep filtration, three-dimensional three-dimensional loose pores formed by the fiber, the surface after rolling, burnt wool and other processes, no fiber shedding, to prevent secondary pollution; silicone oil-free, no chemical release; filter material from inside and outside from loose to dense, forming a gradient filtration, can provide liquid flow and impurity dirt-holding capacity, all types of soft impurities have a superb It is acid resistant but not alkali resistant (because of the ester bond, it will hydrolyze under alkaline conditions and decompose into terephthalic acid and glycol. So in the printing and dyeing plant often put the thin polyester cloth in alkaline conditions for alkali reduction treatment, that is, corrosion off part of it, so that it feels floating, soft, to achieve the purpose of simulation of silk), filtration accuracy range: 0.1 ∽ 250 microns; working temperature should be controlled within 135 ℃. Filter bag processing technology has a bag body line sewing bag mouth steel ring, bag body hot welding bag mouth plastic ring two.

Nylon PA (polyamide) monofilament filter bag: nylon filter bag belongs to the surface filtration, is composed of high-quality nylon monofilament woven smooth screen, the surface opening pore shape is usually square holes, warp and weft intersection after high temperature shaping treatment, will not migrate due to changes in pressure, greater than the filter pore size of all particles intercepted, suitable for intercepting larger rigid particles, can be cleaned and reused a limited number of times. Nylon withstand PH value in 4∽6, filtration accuracy range is generally in 20∽500 mesh, the working temperature should be controlled within 150 ℃. Filter bag processing technology has a bag body line seam (line seam turned inside out) bag mouth steel ring, bag body heat welding bag mouth plastic ring two. Filter bag specification size table

Filter bag specification size tableFilter bag number Filter bag diameter (mm)

Length of filter bag(mm) Filtration area(㎡) Maximum pure water flow rate (T/h) 1#

180

430

0.25

20

2#

180

810

0.5

40

3#

100

210

0.09

6

4#

100

356

0.16

12

5#

236

900

0.66

55

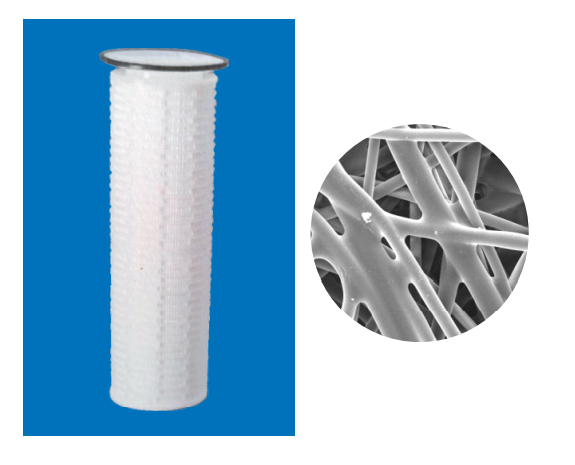

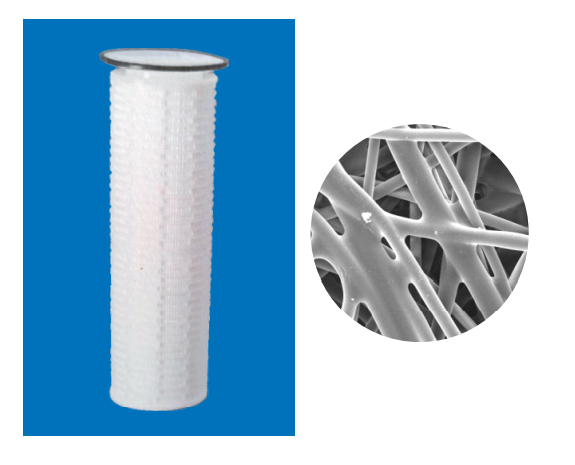

GS-DL152 series bag filter cartridge is made of folded polymer polypropylene filter material, which integrates the advantages of high efficiency and compactness of folded filter cartridge and the features of convenient use and simple operation of filter bag. The area is more than 7 times that of ordinary filter bags, with the advantages of high flow rate, long life and easy to use, etc. It can be replaced and installed on the original standard bag filter #1 and #2 filter bags, which reduces the maintenance cost of the system and reduces the frequency of replacement.

High Flow Folding Bag Filter Cartridge GS-DL152 Series

GS-DL152 series bag filter cartridge is made of folded polymer polypropylene filter material, which combines the advantages of high efficiency and compactness of folded filter cartridge and the features of convenient use and simple operation of filter bag. The area is more than 7 times that of ordinary filter bags, with the advantages of high flow rate, long life and easy to use, etc. It can be installed on the original standard bag filter 1# and 2# filter bags, which reduces the maintenance cost of the system and the frequency of replacement.Main features

Gradual pore size structure, excellent retention efficiency

Large filter area, high flow rate, long life, high dirt holding capacity, wide chemical compatibility, pH range 1-14

Can be installed directly into the housing of most #1 and #2 filter bagsTypical Applications

High flow rate material filtration, process water filtration

Security filtration for reverse osmosis water treatment

Filtration of mineral water, beverages and beerOperating parameters

Maximum operating temperature: <60°C

Maximum working differential pressure: 3.5 bar@23°C (inside-out)

Recommended replacement differential pressure: 1 bar@23°C (inside-out)

Sterilization method: hot water 85°C/60minMaterial structure

Filter material: polypropylene (PP)

Support layer/infusion layer: polypropylene

Skeleton/interface: polypropylene

Sealing ring: see selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter.

Length: 12 inch,25 inch,40 inch,60 inch

Filtration precision (um): 0.45, 1, 3, 5, 10, 20, 40, 50

Filtration area:12(1.8㎡),25(4.1㎡),40(6.6㎡),60(9.8㎡)

Reference maximum flow rate:12 (30m3 /h), 25 (60m3 /h), 40 (80m3 /h), 60 (110m3 /h)

Product specifications See accompanying product quality guarantee

Ordering Information

GS-DL152 Size Filtration accuracy Seals 12=12 inches (330)

25=25 inches(650)

40=40 inches(1016)

60"(1524)

40=40"0045=0.45um

0100=1.0um

0300=3.0um

0500=5.0um

1000=10umE=Ethylene-Propylene

N=Nitrile rubber -

Bag filter is a filtration equipment with a wide range of applications. During filtration, the liquid flows into the filter bag through the inlet pipe on the side of the filter housing, and the bag is supported by a metallic basket, and the liquid penetrates the filter bag through the outlet pipe at the bottom and flows out of the filtration system. The bag filter has the characteristics of simple structure, easy operation, high flow rate and low pressure difference, and is widely used in the chemical, antibiotic, amino acid, beer, beverage and functional sugar industries.

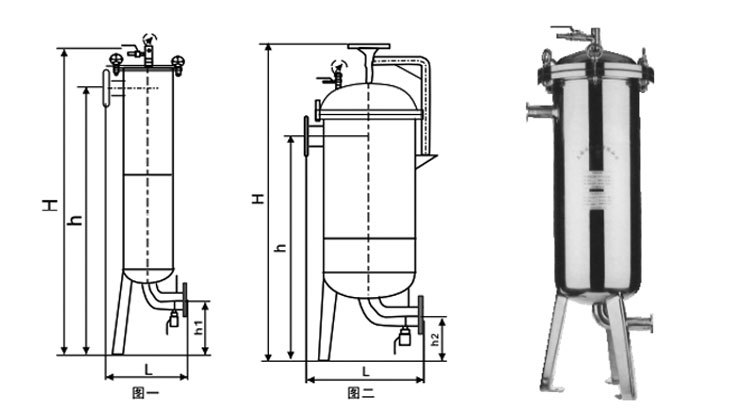

Bag filters are available in single-bag or multi-bag versions, with different numbers of bags depending on the size of the flow rate. The bag filters are designed with a sanitary grade and have a finely polished interior for easy cleaning, with mirror polishing or sandblasting on the surface. Typical bag filters have side inlet and bottom outlet to ensure complete discharge of liquid, and the opening type is quick-open or swing-arm type.

The GS-DS bag filters are available in bag sizes from 1 to 5, and are suitable for different flow rates. The bag materials are mainly polypropylene PP (general purpose), polyester PET (high temperature and solvent resistance) and Neutral NL (large pore size and high throughput and high temperature resistance). Stainless steel rings and plastic rings are available.

♦ Filter bag specification size table

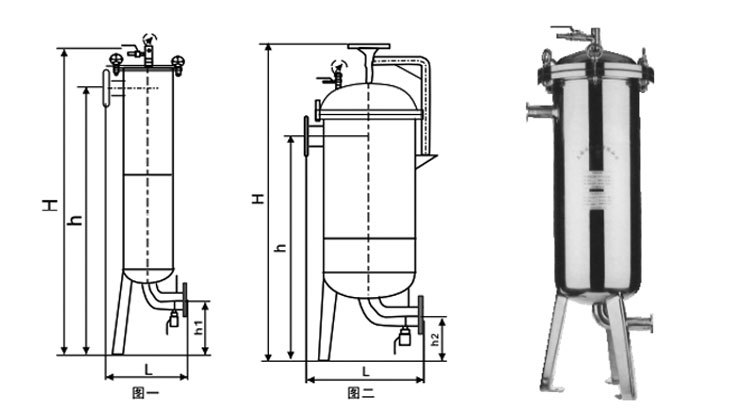

Filter bag number Diameter of filter bag (mm) Length of filter bag (mm) Filter surface area(m²) Maximum pure water flow (m3 /h) 01 180 430 0.25 20 02 180 810 0.50 40 03 100 210 0.09 6 04 100 356 0.16 12 05 200 900 0.66 55 Filter Model Filter bag configuration L

(mm)

H

(mm)

h1

(mm)

h2

(mm)

D

(mm)

Sewage outlet Outline drawing number Recommended inlet and outlet pipes (PN10) Recommend

Flow rate

(T/h)

GS-DS-0103

Ø100×210 1 bag

255

588

500

150

Ø133

G1/2"

Figure 1 DN25

6

GS-DS-0104

Ø100×356 1 bag

255

692

600

150

Ø133

G1/2"

Figure 1 DN32

12

GS-DS-0101

Ø180×430 1 bag

355

930

825

250

Ø219

G1/2"

Figure 1 DN40

20

GS-DS-0102

Ø180×810 1 bag

355

1260

1155

250

Ø219

G1/2"

Figure 1 DN50

40

GS-DS-0105

Ø236×900 1 bag

415

1400

1270

250

Ø273

G3/4"

Figure 1 DN65

55

GS-DS-0202

Ø180×810 2 bag

600

1720

1230

250

Ø450

G1"

Figure 2 DN80

80

GS-DS-0302

Ø180×810 3 bag

650

1815

1300

300

Ø500

G1"

Figure 2 DN100

120

GS-DS-0402

Ø180×810 4 bag

700

1905

1350

300

Ø550

G1"

Figure 2 DN125

160

GS-DS-0502

Ø180×810 5 bag

750

2060

1480

350

Ø600

G1"

Figure 2 DN150

200

GS-DS-0602

Ø180×810 6 bag

850

2055

1450

350

Ø650

G1"

Figure 2 DN150

240

GS-DS-0702

Ø180×810 7 bag

850

2180

1530

350

Ø700

G1"

Figure 1 DN200

280

GS-DS-0802

Ø180×810 8 bag

930

2238

1565

350

Ø750

G1"

Figure 2 DN200

320

GS-DS-0302

Ø180×810 10 bag

1030

2565

1775

350

Ø850

G1"

Figure 2 DN250

400

GS-DS-1202

Ø180×810 12 bag 1125 2687 1850 400 Ø900 G1" Figure 2 DN300 480 Note: Refer to JB/T11713-2013 design, production; flow rate is based on "25 ℃, pure water, filtration precision 5u" test conditions (the actual flow rate may vary due to changes in the viscosity of the liquid, impurity content and differential pressure); import and export flange standard according to "HG/T20592-2009" (according to customer Import and export flange standard according to "HG/T20592-2009" (can be connected with clamps and threaded teeth according to customer requirements).

Ordering Information

GS-DS Number of filter bags Filter bag specifications Filter bag material Seal material Housing material Inlet and outlet connections Interior and exterior surface treatment 01=1 bag

02=2 bag

03=3 bag

04=4 bag

05=5 bag01= 180×430

02= 180×810

03=100×210

04=100×356

05=230×900Polypropylene = PP

Nylon = NL

Polyester = PTS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerBG4=304

BG6=316LF=Flange

K=Clamp

G=ThreadA=Inside and outside polishing

B = inner polished, outer sandblasted matte -

The selection of bag filter is relatively simple, generally according to the physical and chemical properties of the filtered materials to choose the material of the filter housing and the material of the filter bag, according to the filtration needs to achieve the clean requirements to choose the filter bag filtration precision. When the filtration precision is 150µ and above, it is not recommended to choose polypropylene and polyester filter bags, and it is possible to choose stainless steel winding sieve tube cartridge or stainless steel perforated plate composite multi-layer screen cartridge as the filter element of the bag filter.Liquid bag filter design, selection table

Material Basics

Material name Flow rate (T/h) Viscosity (centipoise) PH Value

Name of main solids

Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design

Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size

304 □

316L □

304 inner wall coating PTFE □

PP □

0.6MPa □

1.0MPa □

Clamps□

Flange □

Pagoda Hose □

Filter element material Filter element filtration precision Filter element interface form Filter element and cartridge sealing ring material

Conclusion: Determine the specific model and specification of the filter.

-

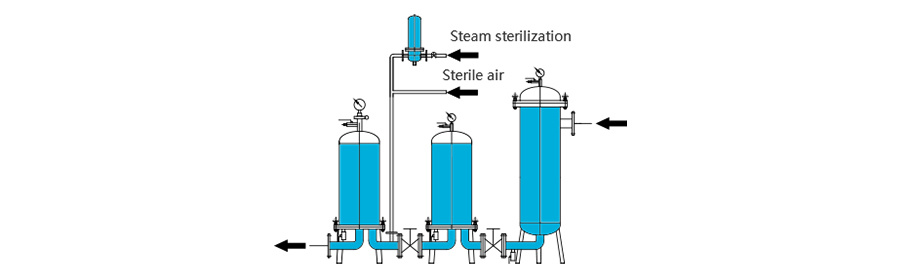

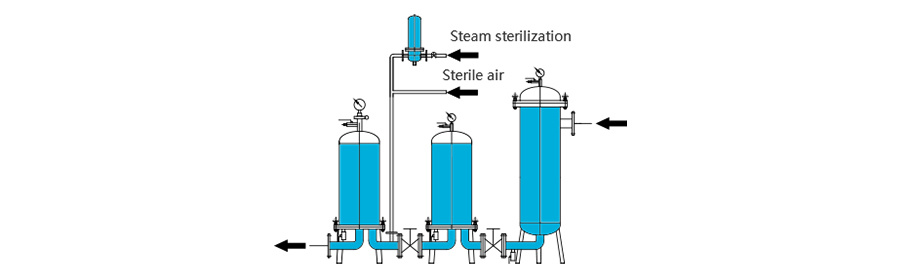

Fermentation aseptic replenishment filtration system

Liquid sterilization filter GS-PES/PTFE/NL type

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. The liquid flows into the bag from the inlet pipe beside the filter housing during filtration...

Steam filter GS-Z type

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Bag filter GS-DS type

Bag filter GS-DS type

Category:

Bag filter GS-DS type

- Description

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Bag filter GS-DS type

- Commodity ID: 994905625676570624

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a very wide range of applications. When filtering, the liquid flows into the filter bag from the inlet tube beside the filter housing, the bag is supported by a metal mesh basket, the liquid penetrates the filter bag through the bottom outlet tube and flows out of the filtration system, the impurity particles are intercepted in the filter bag, and the cleaning or replacement of the filter bag can continue to use. Bag filter has simple structure, easy operation, large flow rate and low pressure difference, etc. It is widely used in biochemical, antibiotic, amino acid, beer, beverage and functional sugar industries.

GS-DS type bag filter bag specifications are 1# bag-5# bag, suitable for different flow rate filtration needs, filter bag materials mainly include polypropylene PP (general-purpose), polyester PET (high temperature and solvent resistance) and nylon NL monofilament screen (large aperture high flux high temperature resistance), filtration accuracy range 0.5 ~ 500µm, suitable for the filtration of different characteristics of the material liquid. The sealing ring has stainless steel ring and plastic ring.

Polypropylene PP filter bag: polypropylene needle felt filter bag belongs to the deep filtration, three-dimensional three-dimensional loose pore formed by the fiber, the surface after rolling light, burnt wool and other processes, no fiber off, to prevent secondary pollution; does not contain silicone oil, no chemical release; filter material from inside and outside from loose to dense, forming a gradient filtration, can provide liquid flow and impurity dirt-holding capacity, for all types of soft impurities have a superb Filtration effect, PH value tolerance wide 1-14, filtration precision range: 0.1250 micron; working temperature should be controlled within 90 ℃. Filter bag processing technology has a bag body wire sewing bag mouth steel ring, bag body hot welding bag mouth plastic ring two.

Polyester PET filter bag: polyester needle felt filter bag belongs to the deep filtration, three-dimensional three-dimensional loose pores formed by the fiber, the surface after rolling, burnt wool and other processes, no fiber shedding, to prevent secondary pollution; silicone oil-free, no chemical release; filter material from inside and outside from loose to dense, forming a gradient filtration, can provide liquid flow and impurity dirt-holding capacity, all types of soft impurities have a superb It is acid resistant but not alkali resistant (because of the ester bond, it will hydrolyze under alkaline conditions and decompose into terephthalic acid and glycol. So in the printing and dyeing plant often put the thin polyester cloth in alkaline conditions for alkali reduction treatment, that is, corrosion off part of it, so that it feels floating, soft, to achieve the purpose of simulation of silk), filtration accuracy range: 0.1 ∽ 250 microns; working temperature should be controlled within 135 ℃. Filter bag processing technology has a bag body line sewing bag mouth steel ring, bag body hot welding bag mouth plastic ring two.

Nylon PA (polyamide) monofilament filter bag: nylon filter bag belongs to the surface filtration, is composed of high-quality nylon monofilament woven smooth screen, the surface opening pore shape is usually square holes, warp and weft intersection after high temperature shaping treatment, will not migrate due to changes in pressure, greater than the filter pore size of all particles intercepted, suitable for intercepting larger rigid particles, can be cleaned and reused a limited number of times. Nylon withstand PH value in 4∽6, filtration accuracy range is generally in 20∽500 mesh, the working temperature should be controlled within 150 ℃. Filter bag processing technology has a bag body line seam (line seam turned inside out) bag mouth steel ring, bag body heat welding bag mouth plastic ring two. Filter bag specification size table

Filter bag specification size tableFilter bag number Filter bag diameter (mm)

Length of filter bag(mm) Filtration area(㎡) Maximum pure water flow rate (T/h) 1#

180

430

0.25

20

2#

180

810

0.5

40

3#

100

210

0.09

6

4#

100

356

0.16

12

5#

236

900

0.66

55

GS-DL152 series bag filter cartridge is made of folded polymer polypropylene filter material, which integrates the advantages of high efficiency and compactness of folded filter cartridge and the features of convenient use and simple operation of filter bag. The area is more than 7 times that of ordinary filter bags, with the advantages of high flow rate, long life and easy to use, etc. It can be replaced and installed on the original standard bag filter #1 and #2 filter bags, which reduces the maintenance cost of the system and reduces the frequency of replacement.

High Flow Folding Bag Filter Cartridge GS-DL152 Series

GS-DL152 series bag filter cartridge is made of folded polymer polypropylene filter material, which combines the advantages of high efficiency and compactness of folded filter cartridge and the features of convenient use and simple operation of filter bag. The area is more than 7 times that of ordinary filter bags, with the advantages of high flow rate, long life and easy to use, etc. It can be installed on the original standard bag filter 1# and 2# filter bags, which reduces the maintenance cost of the system and the frequency of replacement.Main features

Gradual pore size structure, excellent retention efficiency

Large filter area, high flow rate, long life, high dirt holding capacity, wide chemical compatibility, pH range 1-14

Can be installed directly into the housing of most #1 and #2 filter bagsTypical Applications

High flow rate material filtration, process water filtration

Security filtration for reverse osmosis water treatment

Filtration of mineral water, beverages and beerOperating parameters

Maximum operating temperature: <60°C

Maximum working differential pressure: 3.5 bar@23°C (inside-out)

Recommended replacement differential pressure: 1 bar@23°C (inside-out)

Sterilization method: hot water 85°C/60minMaterial structure

Filter material: polypropylene (PP)

Support layer/infusion layer: polypropylene

Skeleton/interface: polypropylene

Sealing ring: see selection table

Sealing technology: adhesive-free thermal fusion sealing technologyCartridge parameters

Outer diameter.

Length: 12 inch,25 inch,40 inch,60 inch

Filtration precision (um): 0.45, 1, 3, 5, 10, 20, 40, 50

Filtration area:12(1.8㎡),25(4.1㎡),40(6.6㎡),60(9.8㎡)

Reference maximum flow rate:12 (30m3 /h), 25 (60m3 /h), 40 (80m3 /h), 60 (110m3 /h)

Product specifications See accompanying product quality guarantee

Ordering Information

GS-DL152 Size Filtration accuracy Seals 12=12 inches (330)

25=25 inches(650)

40=40 inches(1016)

60"(1524)

40=40"0045=0.45um

0100=1.0um

0300=3.0um

0500=5.0um

1000=10umE=Ethylene-Propylene

N=Nitrile rubber -

Bag filter is a filtration equipment with a wide range of applications. During filtration, the liquid flows into the filter bag through the inlet pipe on the side of the filter housing, and the bag is supported by a metallic basket, and the liquid penetrates the filter bag through the outlet pipe at the bottom and flows out of the filtration system. The bag filter has the characteristics of simple structure, easy operation, high flow rate and low pressure difference, and is widely used in the chemical, antibiotic, amino acid, beer, beverage and functional sugar industries.

Bag filters are available in single-bag or multi-bag versions, with different numbers of bags depending on the size of the flow rate. The bag filters are designed with a sanitary grade and have a finely polished interior for easy cleaning, with mirror polishing or sandblasting on the surface. Typical bag filters have side inlet and bottom outlet to ensure complete discharge of liquid, and the opening type is quick-open or swing-arm type.

The GS-DS bag filters are available in bag sizes from 1 to 5, and are suitable for different flow rates. The bag materials are mainly polypropylene PP (general purpose), polyester PET (high temperature and solvent resistance) and Neutral NL (large pore size and high throughput and high temperature resistance). Stainless steel rings and plastic rings are available.

♦ Filter bag specification size table

Filter bag number Diameter of filter bag (mm) Length of filter bag (mm) Filter surface area(m²) Maximum pure water flow (m3 /h) 01 180 430 0.25 20 02 180 810 0.50 40 03 100 210 0.09 6 04 100 356 0.16 12 05 200 900 0.66 55 Filter Model Filter bag configuration L

(mm)

H

(mm)

h1

(mm)

h2

(mm)

D

(mm)

Sewage outlet Outline drawing number Recommended inlet and outlet pipes (PN10) Recommend

Flow rate

(T/h)

GS-DS-0103

Ø100×210 1 bag

255

588

500

150

Ø133

G1/2"

Figure 1 DN25

6

GS-DS-0104

Ø100×356 1 bag

255

692

600

150

Ø133

G1/2"

Figure 1 DN32

12

GS-DS-0101

Ø180×430 1 bag

355

930

825

250

Ø219

G1/2"

Figure 1 DN40

20

GS-DS-0102

Ø180×810 1 bag

355

1260

1155

250

Ø219

G1/2"

Figure 1 DN50

40

GS-DS-0105

Ø236×900 1 bag

415

1400

1270

250

Ø273

G3/4"

Figure 1 DN65

55

GS-DS-0202

Ø180×810 2 bag

600

1720

1230

250

Ø450

G1"

Figure 2 DN80

80

GS-DS-0302

Ø180×810 3 bag

650

1815

1300

300

Ø500

G1"

Figure 2 DN100

120

GS-DS-0402

Ø180×810 4 bag

700

1905

1350

300

Ø550

G1"

Figure 2 DN125

160

GS-DS-0502

Ø180×810 5 bag

750

2060

1480

350

Ø600

G1"

Figure 2 DN150

200

GS-DS-0602

Ø180×810 6 bag

850

2055

1450

350

Ø650

G1"

Figure 2 DN150

240

GS-DS-0702

Ø180×810 7 bag

850

2180

1530

350

Ø700

G1"

Figure 1 DN200

280

GS-DS-0802

Ø180×810 8 bag

930

2238

1565

350

Ø750

G1"

Figure 2 DN200

320

GS-DS-0302

Ø180×810 10 bag

1030

2565

1775

350

Ø850

G1"

Figure 2 DN250

400

GS-DS-1202

Ø180×810 12 bag 1125 2687 1850 400 Ø900 G1" Figure 2 DN300 480 Note: Refer to JB/T11713-2013 design, production; flow rate is based on "25 ℃, pure water, filtration precision 5u" test conditions (the actual flow rate may vary due to changes in the viscosity of the liquid, impurity content and differential pressure); import and export flange standard according to "HG/T20592-2009" (according to customer Import and export flange standard according to "HG/T20592-2009" (can be connected with clamps and threaded teeth according to customer requirements).

Ordering Information

GS-DS Number of filter bags Filter bag specifications Filter bag material Seal material Housing material Inlet and outlet connections Interior and exterior surface treatment 01=1 bag

02=2 bag

03=3 bag

04=4 bag

05=5 bag01= 180×430

02= 180×810

03=100×210

04=100×356

05=230×900Polypropylene = PP

Nylon = NL

Polyester = PTS=Silicone rubber

E=Ethylene-Propylene

V=Fluoroelastomer

T=FluoroelastomerBG4=304

BG6=316LF=Flange

K=Clamp

G=ThreadA=Inside and outside polishing

B = inner polished, outer sandblasted matte -

The selection of bag filter is relatively simple, generally according to the physical and chemical properties of the filtered materials to choose the material of the filter housing and the material of the filter bag, according to the filtration needs to achieve the clean requirements to choose the filter bag filtration precision. When the filtration precision is 150µ and above, it is not recommended to choose polypropylene and polyester filter bags, and it is possible to choose stainless steel winding sieve tube cartridge or stainless steel perforated plate composite multi-layer screen cartridge as the filter element of the bag filter.Liquid bag filter design, selection table

Material Basics

Material name Flow rate (T/h) Viscosity (centipoise) PH Value

Name of main solids

Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design

Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size

304 □

316L □

304 inner wall coating PTFE □

PP □

0.6MPa □

1.0MPa □

Clamps□

Flange □

Pagoda Hose □

Filter element material Filter element filtration precision Filter element interface form Filter element and cartridge sealing ring material

Conclusion: Determine the specific model and specification of the filter.

-

Fermentation aseptic replenishment filtration system

Liquid sterilization filter GS-PES/PTFE/NL type

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. The liquid flows into the bag from the inlet pipe beside the filter housing during filtration...

Steam filter GS-Z type

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters.

Pre