- Products

Basket filter GS-LS/LPG, GS-LS/LPGG type

Basket filter GS-LS/LPG, GS-LS/LPGG type

所属分类:

Basket filter GS-LS/LPG, GS-LS/LPGG type

- Description

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Basket filter GS-LS/LPG, GS-LS/LPGG type

- Commodity ID: 994905491991519232

Basket filter GS-LS/LPG, GS-LS/LPGG type

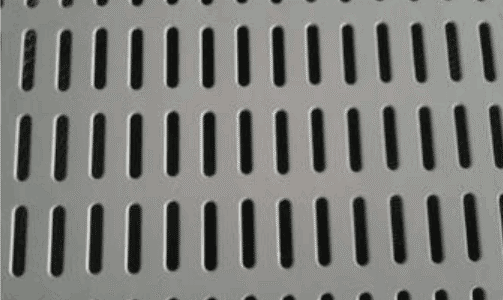

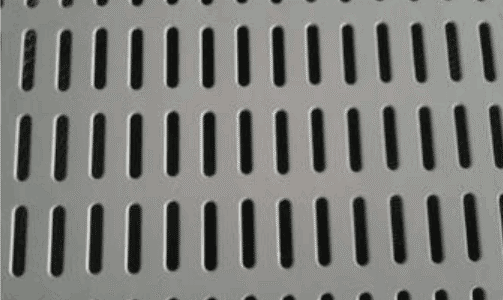

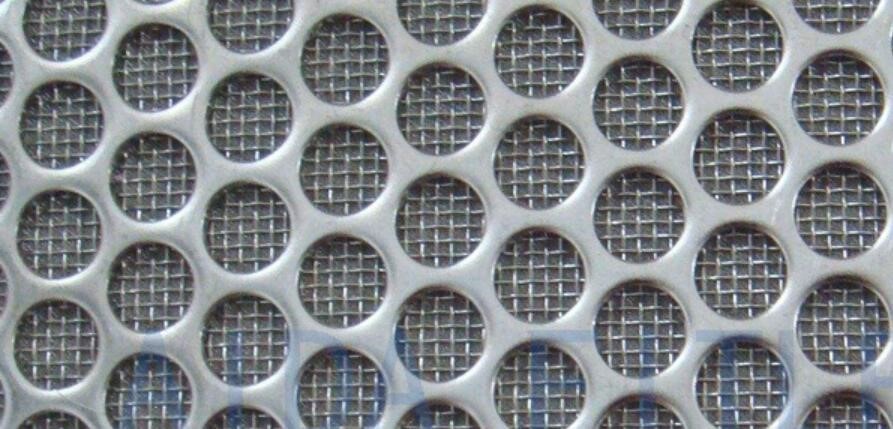

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.I. Perforated plate filter basket

Suitable for larger particle size interception, filtering treatment, pore size 1∽8mm, pore shape have commonly used round, square.Ⅱ、Around the screen tube filter basket

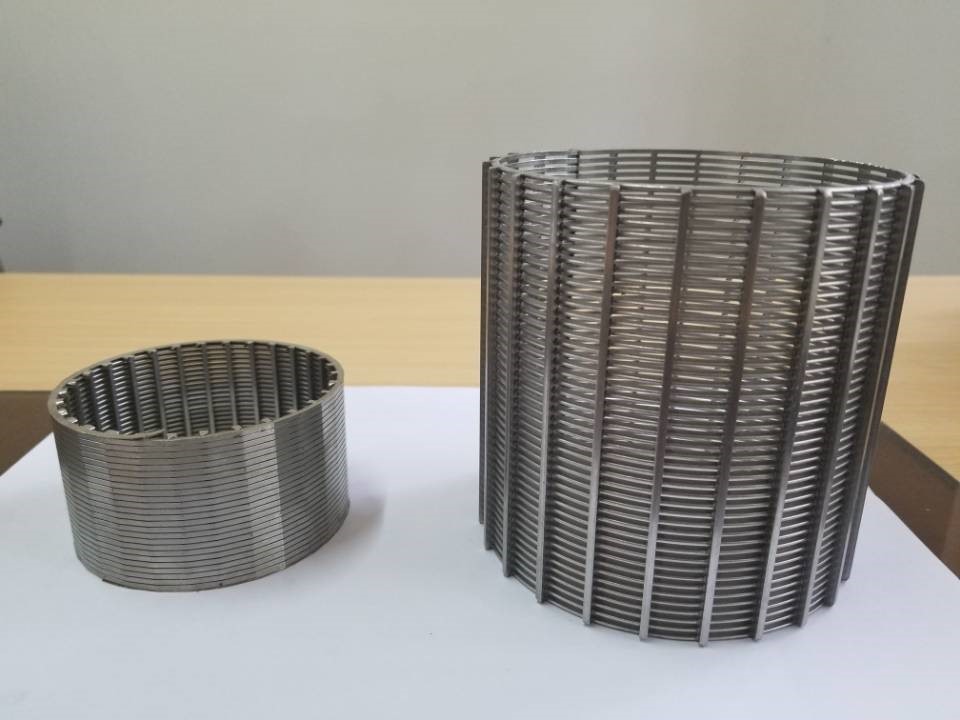

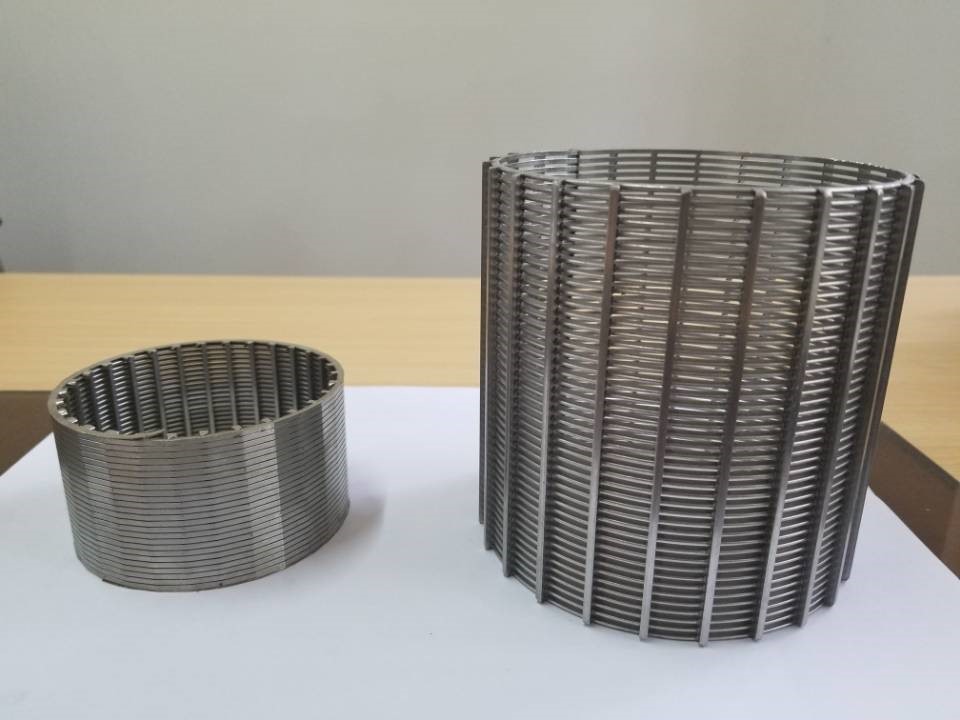

Suitable for larger particle size interception, filtering treatment, pore size 1∽8mm, pore shape have commonly used round, square.Ⅱ、Around the screen tube filter basket Suitable for medium and small particle size interception, filtering treatment, aperture (line gap) 0.075 ∽ 6mm. winding sieve tube is composed of winding wire and support bar, each intersection with fusion connection, solid structure, uniform distribution of water, constant flux flow channel large. There are two forms of internal liquid inlet and external liquid inlet.Ⅲ、Stainless steel perforated plate composite multi-layer screen filter basket

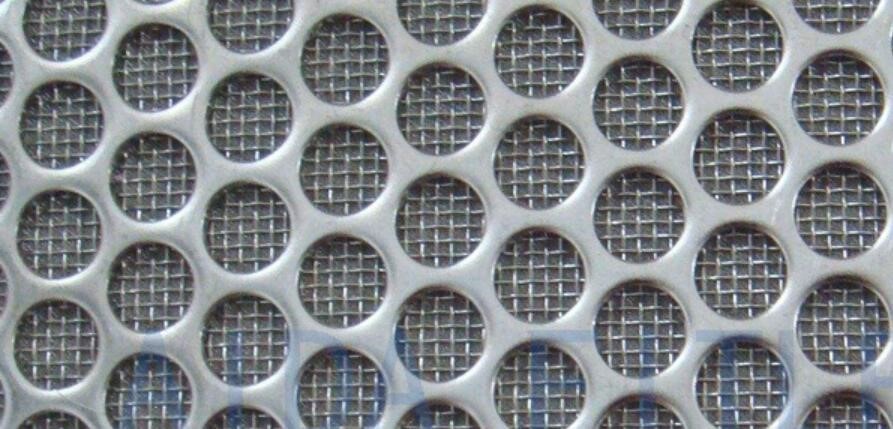

Suitable for medium and small particle size interception, filtering treatment, aperture (line gap) 0.075 ∽ 6mm. winding sieve tube is composed of winding wire and support bar, each intersection with fusion connection, solid structure, uniform distribution of water, constant flux flow channel large. There are two forms of internal liquid inlet and external liquid inlet.Ⅲ、Stainless steel perforated plate composite multi-layer screen filter basket It is suitable for small particle size interception and filtering treatment, with aperture ≦0.07mm. It is made of perforated plate and several layers of square mesh (or dense mesh) compound sintered into one, and the number of layers and mesh composition depends on different use conditions and applications. Because it is the pressure-resistant skeleton and filter mesh sintered into one, so it has a more excellent backwashing effect, as well as the characteristics of small pressure drop loss, is now widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries.

It is suitable for small particle size interception and filtering treatment, with aperture ≦0.07mm. It is made of perforated plate and several layers of square mesh (or dense mesh) compound sintered into one, and the number of layers and mesh composition depends on different use conditions and applications. Because it is the pressure-resistant skeleton and filter mesh sintered into one, so it has a more excellent backwashing effect, as well as the characteristics of small pressure drop loss, is now widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries. -

GS-LS type basket filter

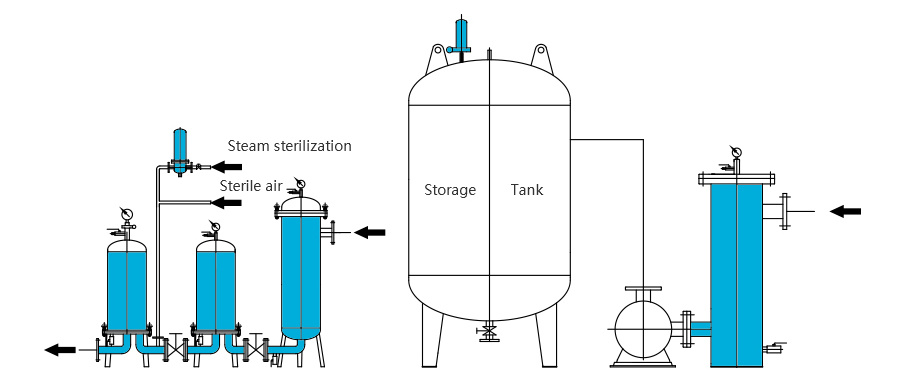

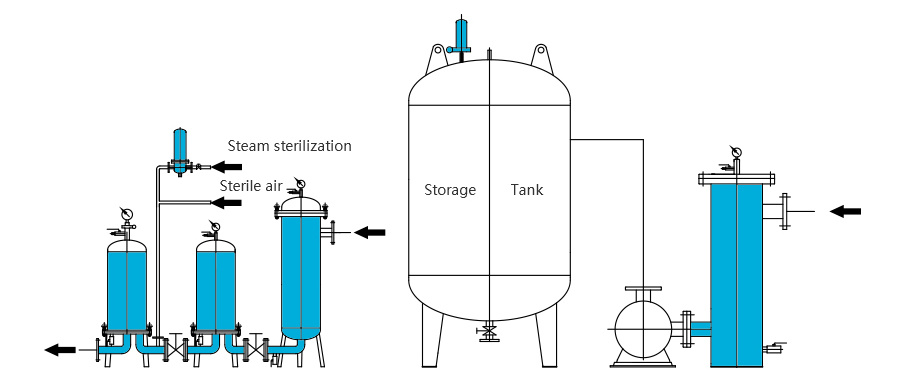

Basket filter is a pressurized filter with filter basket as the filtering element, which can be installed on the pipeline to remove large particles of impurities in the liquid and protect the normal work of pumps, compressors, instruments and other equipment. The filtering area of the filter basket is 2-3 times larger than the area of the pipe diameter. It is much larger than the filtering area of Y-type and T-type filters. Basket filter is mainly composed of receiver, barrel, filter basket, flange, flange cover and fasteners, etc. It is very convenient to use and maintain. Its working principle is that after the fluid enters the filter basket through the barrel, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, unscrew the screw plug at the lower end of the cartridge, drain the fluid, remove the flange cover, take out the filter basket and reload it after cleaning. This product has been widely used in petroleum, chemical, pharmaceutical, food, environmental protection, biological fermentation and other industries. For example, in the biological fermentation industry, the seed medium and fermentation medium are filtered, and the material inlet of even elimination system is filtered, and the fermentation liquid is put into the tank and filtered, etc.

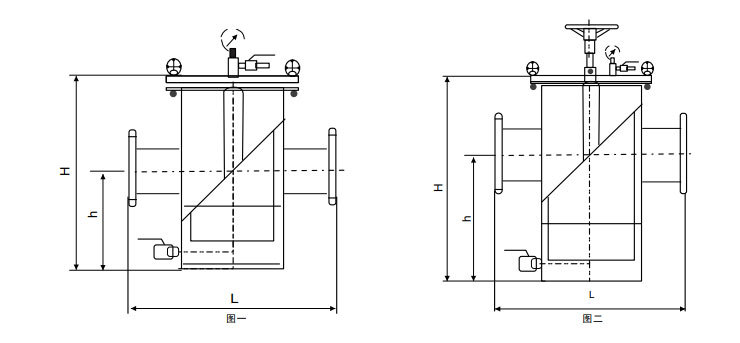

There are two types of basket filters for pipeline designed by our company with reference to JB/T7538-1994 (the current standard number is JB/T7538-2016): GS-LS/LPG type vertical straight-through (inclined mouth mesh type), GS-LS/LPGG type high and low pipe (straight mouth mesh type). The material of the shell is mainly 304 and 316L, and the inner surface of the shell can be sprayed with PTFE anti-corrosion treatment according to the special requirements of the material; the types of filter basket are stainless steel perforated plate, stainless steel winding sieve tube, stainless steel perforated plate compound stainless steel wire mesh; the material of the filter basket is 304 and 316L, and the surface of the filter basket is sprayed with PTFE treatment, in order to apply to the filtration of materials with different characteristics. If the filtered material contains high quality of magnetic metal debris, consider adding a strong magnetic iron bar on the flange cover of the basket filter (the upper flange cover is replaced by a flat cover) to reduce the content of iron ions in the material and improve product quality. That is: the material flows in from the entrance, adsorbed by the strong magnetic rod, filtered out of the filter basket, impurities are intercepted in the filter basket and strong magnetic rod jacket surface, the filter basket and magnetic rod can be replaced or cleaned and continued to use.

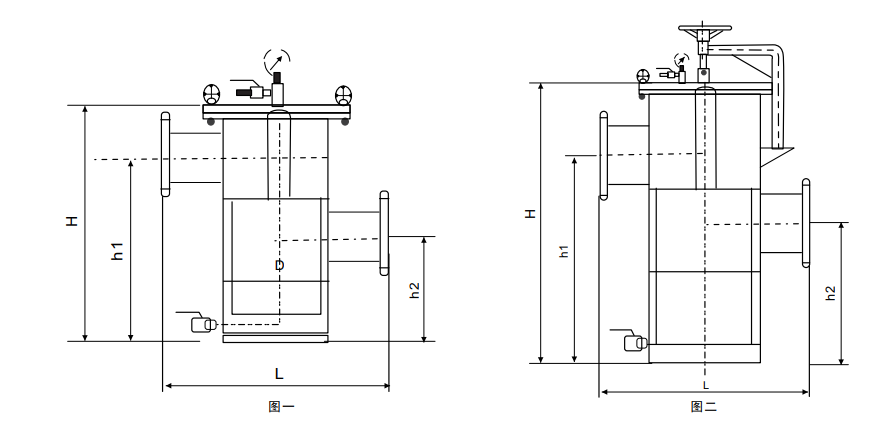

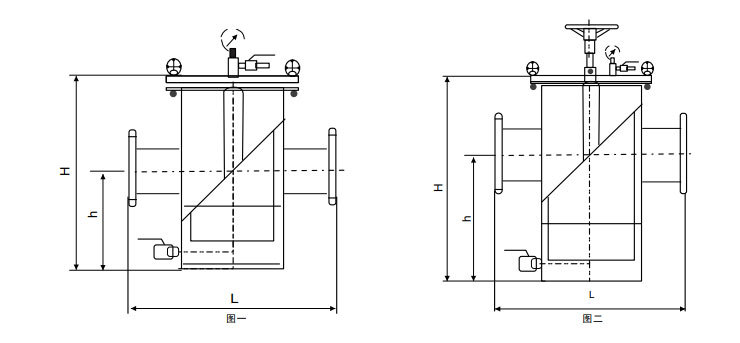

♦ GS-LS/LPG type vertical straight basket strainer (inclined mouth mesh type) dimension table

Nominal diameter

(DN)

Structure size (mm)

Open file size L

Height H

Installation height h

Shell diameter D

Sewage outlet

Figure number Industry standard shell diameter D

10

260

240

170

108(外)

G1/2"

Figure 1 /

15

25

32

300

270

170

133 (outside)

G1/2"

Figure 1 /

40

320

285

180

159 (outside)

G1/2"

Figure 1 108 (outside)

50

400

305

180

219 (outside)

G1/2"

Figure 1 108 (outside) 65

450

395

250

250 (inside)

G1/2"

Figure 1 159 (outside) 80

480

410

250

273 (outside)

G1/2"

Figure 1 194 (outside)

100

500

480

300

300(内)

G1/2"

Figure 1 219 (outside)

125

550

525

350

350 (inside)

G1"

Figure 1 273 (outside)

150

650

575

400

400 (inside)

G1"

Figure 1 350 (inside)

200

750

735

500

500 (within)

G1"

Figure 2 400 (inside)

250

850

885

600

600 (inside)

G1"

Figure 2 500 (within)

300

1000

1010

700

700 (inside)

G1"

Figure 2 600 (inside)

350

1100

1160

800

800 (inside)

G1"

Figure 2 700 (inside)

Note: Import and export flange standards according to “HG/T20592-2009” (can be imported according to customer requirements using clamps, threaded tooth connection)

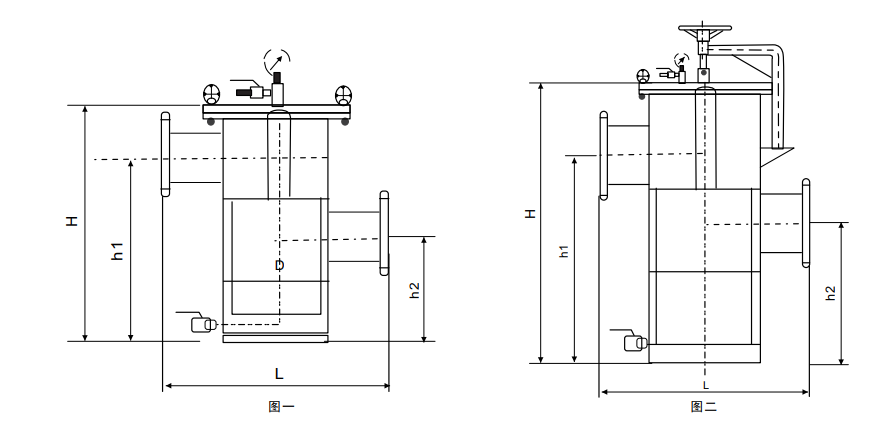

♦ GS-LS/LPGG type high and low receiver basket filter (straight mouth mesh type) appearance size table

Nominal diameter

(DN)

Structure size (mm)

Open file size L

Height H

Installation height h1

Installation height h2

Shell diameter D

Sewage outlet

Figure number Industry standard shell diameter D 10

260 320

250

170

108 (outside)

G1/2"

Figure 1 /

15

25

32

300

320

250

170

133 (outside)

G1/2"

Figure 1 /

40

320

375

280

180

159 (outside)

G1/2"

Figure 1 108 (outside)

50

400

400

300

180

219 (outside)

G1/2"

Figure 1 108 (outside) 65

450

525

400

250

250 (inside)

G1/2"

Figure 1 159 (outside)

80

480

560

420

250

273 (outside)

G1/2"

Figure 1 194 (outside)

100

500

630

470

300

300 (in)

G1/2"

Figure 1 219 (outside)

125

550

725

570

350

350 (inside)

G1"

Figure 1 273 (outside)

150

650

775

620

400

400 (inside)

G1"

Figure 1 350 (inside)

200

750

1035

810

500

500 (inside)

G1"

Figure 2 400 (inside)

250

800

1235

980

600

600 (inside)

G1"

Figure 2 500 (inside)

300

1000

1410

1100

700

700 (inside)

G1"

Figure 2 600 (inside)

350

1100

1660

1300

800

800 (inside)

G1"

Figure 2 700 (inside)

Note: The standard of import and export flange is according to "HG/T20592-2009" (import and export can be connected with clamps and threaded teeth according to the requirements of customers and Uruguay).

Ordering Information

GS-LS Filter basket/shell material Filtration accuracy Filtration accuracy Seal material Structure form BG4=304

BG6=316LF=Flange

K=Clamp

G=Thread0050=0.50mm

0100=1.0mm

0500=5.0mm

1000=10.0mmS=Silicone Rubber

E = EPDM

V=Fluoroelastomer

T=FluoroelastomerLPG

LPGG -

If customers choose our basket filter for filtering low viscosity fluid such as water and steam, they can directly choose the corresponding basket filter model according to the size of the pipeline; if they choose our basket filter for filtering medium and high viscosity materials (such as fermentation medium, high sugar tank inlet filtration, etc.), they can choose the basket filter model corresponding to the size of the pipeline. If the basket filter is installed in front of the pump, it is not suitable to choose too high filtration precision, but if it is installed after the pump, it is possible to choose a higher filtration precision; choose the basket filter material according to the physical and chemical properties of the material.

Liquid basket filter design, selection table

Material Basics

Material name

Flow(T/h)

Viscosity (centipoise)

PH

Name of main solids

Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design

Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size

304 □

316L □

304 inner wall coating PTFE □

0.6MPa □

1.0MPa □

1.6MPa □

Clamp □

Flange □

Pagoda hose □

Filter basket material

Filter basket filtration precision Filter basket structure form Filter basket and cartridge sealing ring material Conclusion: Determine the specific model and specification of the filter.

Note: In order to facilitate customers to determine the filtration accuracy of the filter basket, a conversion table of "mesh, micron and millimeter" is attached.

Screen mesh and aperture comparison table

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

2

8000

8.00

28

600

0.600

100

150

0.150

250

58

0.0580

3

6700

6.70

30

550

0.550

115

125

0.125

270

53

0.0530

4

4750

4.75

32

500

0.500

120

120

0.120

300

48

0.0480

5

4000

4.00

35

425

0.425

125

115

0.115

325

45

0.0450

6

3350

3.35

40

380

0.380

130

113

0.113

400

38

0.0380

7

2800

2.80

42

355

0.355

140

109

0.109

500

25

0.0250

8

2360

2.36

45

325

0.325

150

106

0.106

600

23

0.0230

10

1700

1.70

48

300

0.300

160

96

0.096

800

18

0.0180

12

1400

1.40

50

270

0.270

170

90

0.090

1000

13

0.0130

14

1180

1.18

60

250

0.250

175

86

0.086

1340

10

0.0100

16

1000

1.00

65

230

0.230

180

80

0.080

2000

6.5

0.0065

18

880

0.88

70

212

0.212

200

75

0.075

5000

2.6

0.0026

20

830

0.83

80

180

0.180

230

62

0.062

8000

1.6

0.0016

24

700

0.70

90

160

0.160

240

61

0.061

10000

1.3

0.0013

Note: Basic conversion rule: screen inner diameter (µm) ≈ 14832.4/number of screen mesh.

-

Material removal, clarification, aseptic filtration system

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. When filtering, the liquid flows into the bag from the inlet pipe beside the filter housing, and the bag is supported by a metal mesh basket...

Basket filter GS-LS/LPG, GS-LS/LPGG type

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters, and can also be used for steam filtration in other places.

Sterilization grade air respirator GS-HX type

GS-HX type sterilization air respirator is suitable for installation on the air exchange hole of various types of liquid storage tanks, pure water tanks and sterile dry boxes for sterilization and filtration of gas during gas exchange

Basket filter GS-LS/LPG, GS-LS/LPGG type

Basket filter GS-LS/LPG, GS-LS/LPGG type

Category:

Basket filter GS-LS/LPG, GS-LS/LPGG type

- Description

- Housing

- Design and selection instructions

- 产品链接

-

- Commodity name: Basket filter GS-LS/LPG, GS-LS/LPGG type

- Commodity ID: 994905491991519232

Basket filter GS-LS/LPG, GS-LS/LPGG type

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.I. Perforated plate filter basket

Suitable for larger particle size interception, filtering treatment, pore size 1∽8mm, pore shape have commonly used round, square.Ⅱ、Around the screen tube filter basket

Suitable for larger particle size interception, filtering treatment, pore size 1∽8mm, pore shape have commonly used round, square.Ⅱ、Around the screen tube filter basket Suitable for medium and small particle size interception, filtering treatment, aperture (line gap) 0.075 ∽ 6mm. winding sieve tube is composed of winding wire and support bar, each intersection with fusion connection, solid structure, uniform distribution of water, constant flux flow channel large. There are two forms of internal liquid inlet and external liquid inlet.Ⅲ、Stainless steel perforated plate composite multi-layer screen filter basket

Suitable for medium and small particle size interception, filtering treatment, aperture (line gap) 0.075 ∽ 6mm. winding sieve tube is composed of winding wire and support bar, each intersection with fusion connection, solid structure, uniform distribution of water, constant flux flow channel large. There are two forms of internal liquid inlet and external liquid inlet.Ⅲ、Stainless steel perforated plate composite multi-layer screen filter basket It is suitable for small particle size interception and filtering treatment, with aperture ≦0.07mm. It is made of perforated plate and several layers of square mesh (or dense mesh) compound sintered into one, and the number of layers and mesh composition depends on different use conditions and applications. Because it is the pressure-resistant skeleton and filter mesh sintered into one, so it has a more excellent backwashing effect, as well as the characteristics of small pressure drop loss, is now widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries.

It is suitable for small particle size interception and filtering treatment, with aperture ≦0.07mm. It is made of perforated plate and several layers of square mesh (or dense mesh) compound sintered into one, and the number of layers and mesh composition depends on different use conditions and applications. Because it is the pressure-resistant skeleton and filter mesh sintered into one, so it has a more excellent backwashing effect, as well as the characteristics of small pressure drop loss, is now widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries. -

GS-LS type basket filter

Basket filter is a pressurized filter with filter basket as the filtering element, which can be installed on the pipeline to remove large particles of impurities in the liquid and protect the normal work of pumps, compressors, instruments and other equipment. The filtering area of the filter basket is 2-3 times larger than the area of the pipe diameter. It is much larger than the filtering area of Y-type and T-type filters. Basket filter is mainly composed of receiver, barrel, filter basket, flange, flange cover and fasteners, etc. It is very convenient to use and maintain. Its working principle is that after the fluid enters the filter basket through the barrel, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, unscrew the screw plug at the lower end of the cartridge, drain the fluid, remove the flange cover, take out the filter basket and reload it after cleaning. This product has been widely used in petroleum, chemical, pharmaceutical, food, environmental protection, biological fermentation and other industries. For example, in the biological fermentation industry, the seed medium and fermentation medium are filtered, and the material inlet of even elimination system is filtered, and the fermentation liquid is put into the tank and filtered, etc.

There are two types of basket filters for pipeline designed by our company with reference to JB/T7538-1994 (the current standard number is JB/T7538-2016): GS-LS/LPG type vertical straight-through (inclined mouth mesh type), GS-LS/LPGG type high and low pipe (straight mouth mesh type). The material of the shell is mainly 304 and 316L, and the inner surface of the shell can be sprayed with PTFE anti-corrosion treatment according to the special requirements of the material; the types of filter basket are stainless steel perforated plate, stainless steel winding sieve tube, stainless steel perforated plate compound stainless steel wire mesh; the material of the filter basket is 304 and 316L, and the surface of the filter basket is sprayed with PTFE treatment, in order to apply to the filtration of materials with different characteristics. If the filtered material contains high quality of magnetic metal debris, consider adding a strong magnetic iron bar on the flange cover of the basket filter (the upper flange cover is replaced by a flat cover) to reduce the content of iron ions in the material and improve product quality. That is: the material flows in from the entrance, adsorbed by the strong magnetic rod, filtered out of the filter basket, impurities are intercepted in the filter basket and strong magnetic rod jacket surface, the filter basket and magnetic rod can be replaced or cleaned and continued to use.

♦ GS-LS/LPG type vertical straight basket strainer (inclined mouth mesh type) dimension table

Nominal diameter

(DN)

Structure size (mm)

Open file size L

Height H

Installation height h

Shell diameter D

Sewage outlet

Figure number Industry standard shell diameter D

10

260

240

170

108(外)

G1/2"

Figure 1 /

15

25

32

300

270

170

133 (outside)

G1/2"

Figure 1 /

40

320

285

180

159 (outside)

G1/2"

Figure 1 108 (outside)

50

400

305

180

219 (outside)

G1/2"

Figure 1 108 (outside) 65

450

395

250

250 (inside)

G1/2"

Figure 1 159 (outside) 80

480

410

250

273 (outside)

G1/2"

Figure 1 194 (outside)

100

500

480

300

300(内)

G1/2"

Figure 1 219 (outside)

125

550

525

350

350 (inside)

G1"

Figure 1 273 (outside)

150

650

575

400

400 (inside)

G1"

Figure 1 350 (inside)

200

750

735

500

500 (within)

G1"

Figure 2 400 (inside)

250

850

885

600

600 (inside)

G1"

Figure 2 500 (within)

300

1000

1010

700

700 (inside)

G1"

Figure 2 600 (inside)

350

1100

1160

800

800 (inside)

G1"

Figure 2 700 (inside)

Note: Import and export flange standards according to “HG/T20592-2009” (can be imported according to customer requirements using clamps, threaded tooth connection)

♦ GS-LS/LPGG type high and low receiver basket filter (straight mouth mesh type) appearance size table

Nominal diameter

(DN)

Structure size (mm)

Open file size L

Height H

Installation height h1

Installation height h2

Shell diameter D

Sewage outlet

Figure number Industry standard shell diameter D 10

260 320

250

170

108 (outside)

G1/2"

Figure 1 /

15

25

32

300

320

250

170

133 (outside)

G1/2"

Figure 1 /

40

320

375

280

180

159 (outside)

G1/2"

Figure 1 108 (outside)

50

400

400

300

180

219 (outside)

G1/2"

Figure 1 108 (outside) 65

450

525

400

250

250 (inside)

G1/2"

Figure 1 159 (outside)

80

480

560

420

250

273 (outside)

G1/2"

Figure 1 194 (outside)

100

500

630

470

300

300 (in)

G1/2"

Figure 1 219 (outside)

125

550

725

570

350

350 (inside)

G1"

Figure 1 273 (outside)

150

650

775

620

400

400 (inside)

G1"

Figure 1 350 (inside)

200

750

1035

810

500

500 (inside)

G1"

Figure 2 400 (inside)

250

800

1235

980

600

600 (inside)

G1"

Figure 2 500 (inside)

300

1000

1410

1100

700

700 (inside)

G1"

Figure 2 600 (inside)

350

1100

1660

1300

800

800 (inside)

G1"

Figure 2 700 (inside)

Note: The standard of import and export flange is according to "HG/T20592-2009" (import and export can be connected with clamps and threaded teeth according to the requirements of customers and Uruguay).

Ordering Information

GS-LS Filter basket/shell material Filtration accuracy Filtration accuracy Seal material Structure form BG4=304

BG6=316LF=Flange

K=Clamp

G=Thread0050=0.50mm

0100=1.0mm

0500=5.0mm

1000=10.0mmS=Silicone Rubber

E = EPDM

V=Fluoroelastomer

T=FluoroelastomerLPG

LPGG -

If customers choose our basket filter for filtering low viscosity fluid such as water and steam, they can directly choose the corresponding basket filter model according to the size of the pipeline; if they choose our basket filter for filtering medium and high viscosity materials (such as fermentation medium, high sugar tank inlet filtration, etc.), they can choose the basket filter model corresponding to the size of the pipeline. If the basket filter is installed in front of the pump, it is not suitable to choose too high filtration precision, but if it is installed after the pump, it is possible to choose a higher filtration precision; choose the basket filter material according to the physical and chemical properties of the material.

Liquid basket filter design, selection table

Material Basics

Material name

Flow(T/h)

Viscosity (centipoise)

PH

Name of main solids

Solids content(%) Bulk particle size distribution of solids (µm) Solids recovery/clarification and debris removal Filter design

Filter housing material Filter working temperature(℃) Filter working pressure (MPa) Filter inlet and outlet connection method and size

304 □

316L □

304 inner wall coating PTFE □

0.6MPa □

1.0MPa □

1.6MPa □

Clamp □

Flange □

Pagoda hose □

Filter basket material

Filter basket filtration precision Filter basket structure form Filter basket and cartridge sealing ring material Conclusion: Determine the specific model and specification of the filter.

Note: In order to facilitate customers to determine the filtration accuracy of the filter basket, a conversion table of "mesh, micron and millimeter" is attached.

Screen mesh and aperture comparison table

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

(mesh)

(µm)

(mm)

2

8000

8.00

28

600

0.600

100

150

0.150

250

58

0.0580

3

6700

6.70

30

550

0.550

115

125

0.125

270

53

0.0530

4

4750

4.75

32

500

0.500

120

120

0.120

300

48

0.0480

5

4000

4.00

35

425

0.425

125

115

0.115

325

45

0.0450

6

3350

3.35

40

380

0.380

130

113

0.113

400

38

0.0380

7

2800

2.80

42

355

0.355

140

109

0.109

500

25

0.0250

8

2360

2.36

45

325

0.325

150

106

0.106

600

23

0.0230

10

1700

1.70

48

300

0.300

160

96

0.096

800

18

0.0180

12

1400

1.40

50

270

0.270

170

90

0.090

1000

13

0.0130

14

1180

1.18

60

250

0.250

175

86

0.086

1340

10

0.0100

16

1000

1.00

65

230

0.230

180

80

0.080

2000

6.5

0.0065

18

880

0.88

70

212

0.212

200

75

0.075

5000

2.6

0.0026

20

830

0.83

80

180

0.180

230

62

0.062

8000

1.6

0.0016

24

700

0.70

90

160

0.160

240

61

0.061

10000

1.3

0.0013

Note: Basic conversion rule: screen inner diameter (µm) ≈ 14832.4/number of screen mesh.

-

Material removal, clarification, aseptic filtration system

Liquid Fine Filter GS-PES/NL/PTFE/PVDF

GS-PES cartridge adopts US imported asymmetric polyethersulfone membrane, which has reliable retention efficiency, high flux, low protein adsorption performance and good anti-pollution ability

Liquid pre-filter GS-PP type / GS-PP ZP type

The new generation GS-PP series cartridge is made of sub-micron grade fiber with smaller fiber diameter, featuring large void ratio, high particle retention efficiency, large flux and long service life.

Bag filter GS-DS type

Bag filter is a kind of filtration equipment with a wide range of applications. When filtering, the liquid flows into the bag from the inlet pipe beside the filter housing, and the bag is supported by a metal mesh basket...

Basket filter GS-LS/LPG, GS-LS/LPGG type

The filter basket materials are stainless steel perforated plate, stainless steel winding screen tube, stainless steel perforated plate composite multi-layer screen; filter basket materials are 304 and 316L, as well as filter basket surface spraying PTFE treatment, in order to apply to the filtration of different characteristics of the material liquid.

Steam filter GS-Z

GS-Z, GS-Ti and GS-BG series steam filters are mainly used for online steam sterilization matching filtration of air sterilization filters, and can also be used for steam filtration in other places.

Sterilization grade air respirator GS-HX type

GS-HX type sterilization air respirator is suitable for installation on the air exchange hole of various types of liquid storage tanks, pure water tanks and sterile dry boxes for sterilization and filtration of gas during gas exchange

Pre