- Products

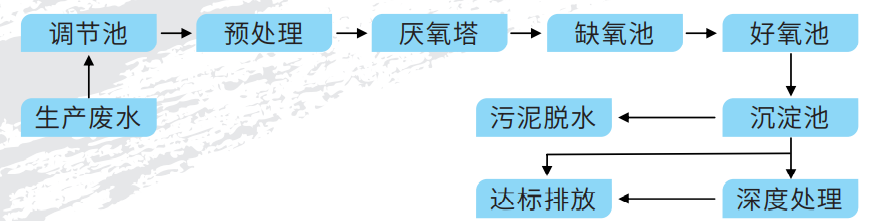

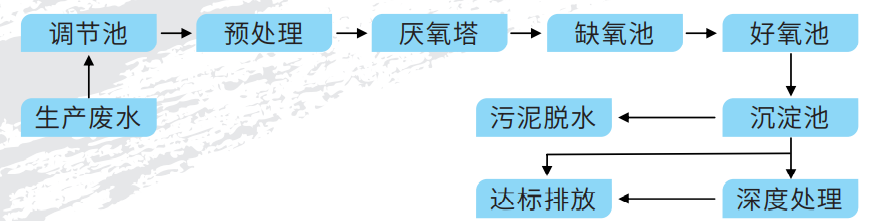

Flow chart of biological fermentation production wastewater treatment project

Flow chart of biological fermentation production wastewater treatment project

所属分类:

Biological fermentation wastewater treatment process flow sketch

- Description

- 产品链接

-

- Commodity name: Flow chart of biological fermentation production wastewater treatment project

- Commodity ID: 994905886339981312

Flow chart of biological fermentation production wastewater treatment project

Characteristics of fermentation wastewater:- Rich in non-degradable organic matter and biotoxic substances

- High ammonia nitrogen

- High chromaticity

- High pH fluctuation

- Intermittent discharge

- High treatment cost

- Difficult to treat

Introduction to Membrane Bioreactor (MBR) technology:MBR technology is a new, highly efficient wastewater treatment process that combines highly efficient membrane separation technology with the traditional activated sludge method, using a submerged membrane module with a unique structure that is placed in an aeration tank.

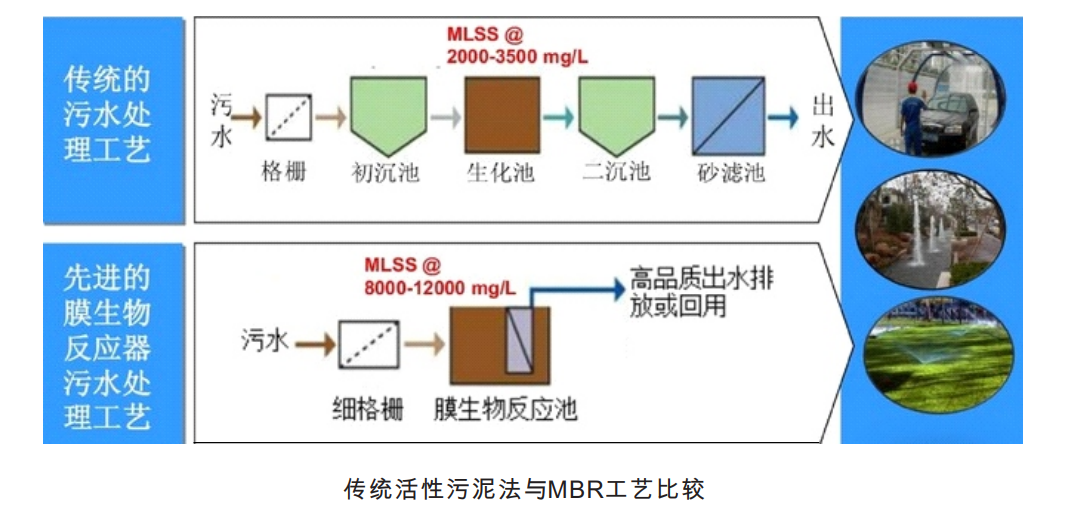

Introduction to Membrane Bioreactor (MBR) technology:MBR technology is a new, highly efficient wastewater treatment process that combines highly efficient membrane separation technology with the traditional activated sludge method, using a submerged membrane module with a unique structure that is placed in an aeration tank. Advantages of MBR membrane wastewater treatment technology compared to traditional activated sludge method.

Advantages of MBR membrane wastewater treatment technology compared to traditional activated sludge method.Assembly type membrane frame design is convenient and flexible, easy disassembly and maintenance of membrane modules, and fast start-up of process commissioning

High concentration of activated sludge enhances the efficiency of chemical treatment

Effective retention of small and slow-growing nitrifying bacteria, and good denitrification effect

Longer sludge discharge cycle, lower sludge production rate, and lower sludge treatment cost

Eliminates the need for a second settling tank, saving space

Highly effective in retaining microorganisms and various pathogenic bacteria, and the effluent is clean and can be directly reused

The water quality is good and can be used directly with reverse osmosis systems to produce higher quality reusable water.In addition, the company has applied its own intellectual property plate membrane products (invention patents ZL201410549146.1 and ZL201410550404.8) to the water treatment process, which has the advantages of easy control of process costs and timely process service.

Flow chart of biological fermentation production wastewater treatment project

Flow chart of biological fermentation production wastewater treatment project

Category:

Biological fermentation wastewater treatment process flow sketch

- Description

- 产品链接

-

- Commodity name: Flow chart of biological fermentation production wastewater treatment project

- Commodity ID: 994905886339981312

Flow chart of biological fermentation production wastewater treatment project

Characteristics of fermentation wastewater:- Rich in non-degradable organic matter and biotoxic substances

- High ammonia nitrogen

- High chromaticity

- High pH fluctuation

- Intermittent discharge

- High treatment cost

- Difficult to treat

Introduction to Membrane Bioreactor (MBR) technology:MBR technology is a new, highly efficient wastewater treatment process that combines highly efficient membrane separation technology with the traditional activated sludge method, using a submerged membrane module with a unique structure that is placed in an aeration tank.

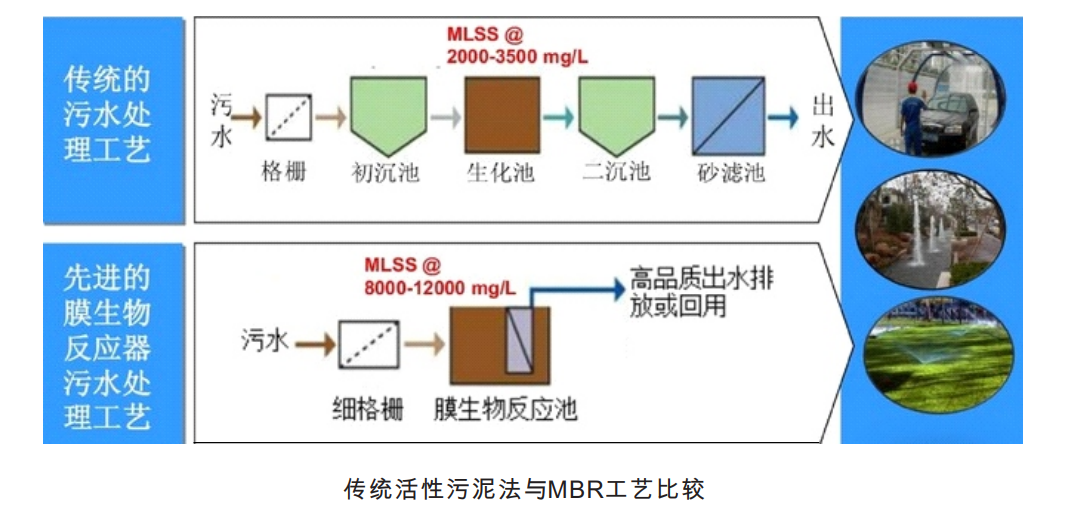

Introduction to Membrane Bioreactor (MBR) technology:MBR technology is a new, highly efficient wastewater treatment process that combines highly efficient membrane separation technology with the traditional activated sludge method, using a submerged membrane module with a unique structure that is placed in an aeration tank. Advantages of MBR membrane wastewater treatment technology compared to traditional activated sludge method.

Advantages of MBR membrane wastewater treatment technology compared to traditional activated sludge method.Assembly type membrane frame design is convenient and flexible, easy disassembly and maintenance of membrane modules, and fast start-up of process commissioning

High concentration of activated sludge enhances the efficiency of chemical treatment

Effective retention of small and slow-growing nitrifying bacteria, and good denitrification effect

Longer sludge discharge cycle, lower sludge production rate, and lower sludge treatment cost

Eliminates the need for a second settling tank, saving space

Highly effective in retaining microorganisms and various pathogenic bacteria, and the effluent is clean and can be directly reused

The water quality is good and can be used directly with reverse osmosis systems to produce higher quality reusable water.In addition, the company has applied its own intellectual property plate membrane products (invention patents ZL201410549146.1 and ZL201410550404.8) to the water treatment process, which has the advantages of easy control of process costs and timely process service.

Pre